Precision Ag Technology Moves Forward For Vegetable Growers

The Western Growers (WG) Center for Innovation & Technology now has 24 startup or “resident” companies under its wing. When the center opened in December 2015, that number was six.

The center, located in Salinas, CA, is a place for innovators and growers to gather and brainstorm, looking for solutions to agriculture’s biggest problems. Focusing on technology, some of the center’s startups are looking for new ways to move forward with labor, water conservation, and overall sustainability.

Being associated with the center gives these companies an extra boost as WG promotes the startups through webinars and its newsletter, opening up each startup company’s offerings to its 2,400 members.

American Vegetable Grower® magazine recently sat down with principal players from three of the startups to find out what they hope to contribute to agriculture and to your business.

TerrAvion Inc.: Aerial Imagery

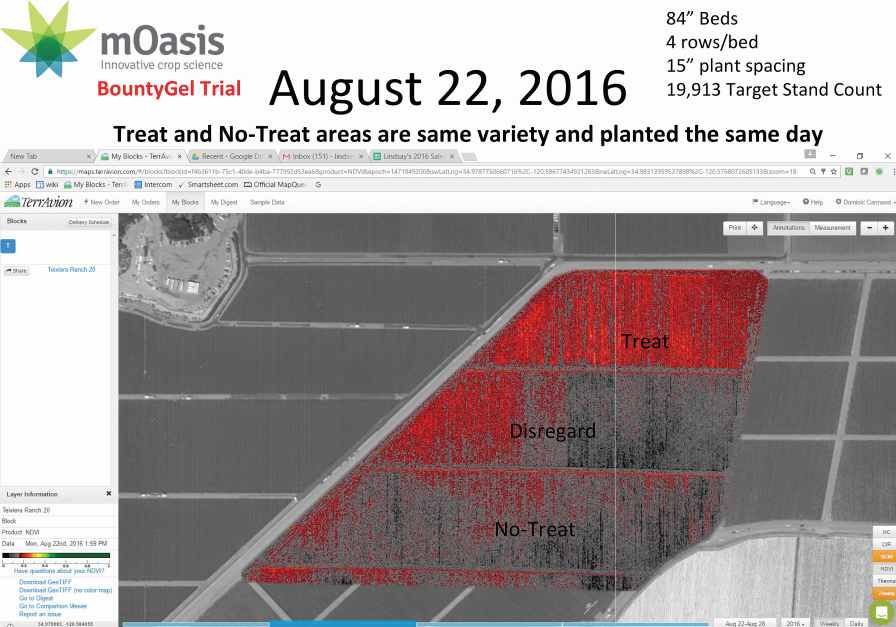

A product designed to improve the efficient use of water in the soil was applied pre-plant to the treated area in this strawberry field image. TerrAvion’s imagery illuminates the enhanced vigor of the treated versus non-treated area of this field. Photo courtesy of Lindsay Hutchinson

TerrAvion is a weekly aerial imagery subscription service that provides high-level resolution using fixed-wing piloted aircraft. The company has helped growers with yield forecasting, pest management, irrigation optimization, and labor savings.

TerrAvion’s Vice President, Lindsay Hutchinson, who spent more than 30 years in the vegetable seed business with Seminis/Monsanto, says he honed his skills on how to analyze ag technologies and introduce the benefits to growers by concentrating on genetics. He has now moved onto another technology focusing on aerial imaging.

Hutchinson says Terr-Avion is growing in several crop areas including winegrapes, citrus, open-field and center-pivot crops, strawberries, lettuce, and other vegetables.

“We will be introducing a Viable Vegetation Index solution within the next few months focusing initially on lettuce,” he says. “The index is a percent of viable vegetation in the imaged acreage, removing all the stunted and dead plants in the row and surface soil in the furrows. This index (percentage) is applied to the target stand count (bed width, number of rows per bed, spacing between plants in the row) and will provide growers with the current viable percent of the target plant stand. Growers will be provided a different perspective by illuminating growth patterns weekly and tracking this index.”

Each week, Hutchinson performs ground truthing on newly imaged fields. “Ground truthing is investigating anomalies in the imagery, visiting the specific spot in the field with the aid of TerrAvion’s iOS app, and capturing metrics and photos of issues for grower clients,” he says.

The company’s OverView iOS app allows growers and PCAs to use the real-time imagery and go to the specific spot of interest in the field.

“Using the app, in conjunction with TerrAvion’s OverView services, provides the growers with pinpoint accuracy while investigating issues in their fields,” he says. “Growers aren’t just getting a pretty picture of the field any more. With weekly imaging, they’re able to identify specific problem areas in a field, do something about it, and track their progress.”

Food Origins: Precision Harvest Data

Food Origin’s technology involves collecting data from field workers

harvesting products and using that information for payroll, food safety, etc. Photo courtesy of Nathan Dorn

As the company name (Food Origins) implies, this operation traces back hand-harvested produce to where it was picked. Nathan Dorn, Founder and CEO, explains it as being a “hardware-enabled, software-service company that does traceability and more.”

Dorn says the technology involves precision yield measurement through low-cost GPS IOT (Internet Of Things) devices. Essentially, the technology involves collecting data from field workers harvesting and using that information for payroll, production, and food safety. Dorn compares the technology to a Fit Bit.

“The technology captures precision data with the lowest burden to harvesters and sends it to the Cloud for analytical work,” he explains. “We are able to provide scoreboards to harvesters, growers, marketers, retailers, and consumers of important data they have not had visibility to before. Because of the way we get data through our devices, now we can share the data back to the people doing the work as conditions are constantly changing for harvesters, and gro-wers can make decisions from that information in real time.”

Growers can use this data to reposition resources to complete the harvest and get the fresh produce out of the field before it rots. “For the farmer, what is picked in the field is revenue, and only when we can bring in the crop do we get the opportunity to sell it,” he says. “If we can get the best people working in the field, that means more money for the worker, revenue and savings to the grower, and a savings to the consumer.”

People talk about transparency from farm to fork, Dorn says, but there are few products consumers pay extra for to achieve this. With Food Origins, transparency data is built into the process and growers can capture and share information on product origin.

The technology is still in the prototype and field trial phase, but the plan is for it to be available to all hand-picked specialty crops in 2017.

WaterBit: Real-Time Sensing

WaterBit’s wireless moisture sensor works in any soil type.

Photo courtesy of Manu Pillai

Manu Pillai, the founder of WaterBit, grew up in Northwest Nigeria and was well-versed in the problems stemming from drought. His father worked for the United Nations, and as Pillai says, “He spent a lot of time fixing things.”

Like his father, Pillai wants to “fix things,” but in a different way. He didn’t have a modern, industrial ag background, but had built laptop computers, software, cellular networks, and imaging systems, and saw an opportunity to do something different.

“With less good water available globally, I knew that bad water doesn’t grow good food. I decided this was something I could work on,” he says.

To make more money with less effort, growers need accurate moisture sensors so they know when crops need water or additional nutrients, Pillai explains. Current sensor prices are between $5,000 and $8,000 installed, and can include a maintenance fee. WaterBit plans to have the sensors available for $300 installed, with a $300 per year fee that includes everything from radio systems to data transfer to software application.

To make a sensor that is low cost and functional, Pillai and his team have reduced the power consumption and the unit runs on a battery that will last at least an entire season.

There is no need for a solar panel, as is the case for other sensors since power consumption is low for both sensor and radio. Pillai was able to demonstrate that when the sensor worked through 3.6 miles of dense citrus, which includes thick leaves and reduces radio-range performance.

Further helping to reduce costs, a few hundred sensors can share a cellular connection and they are capable of working in any type of soil, he says.

More than 10 large growers have agreed to purchase or trial the sensors when they are available in November and more than 20 additional farms are waiting for the product.

“By 2018, we will be able to offer growers [the ability] to control one 5-by-3-foot area, with the goal of getting moisture sensing and control down to one plant,” he adds.