Citrus Groves Of The Future

There is an old saying in citrus that goes something like this: “The best sign of a top-notch grower is to see his footprints in the grove.” With all the challenges of the day, the adage is more true than ever. Bill Barber, who is vice president/general manager of Lykes Bros. Citrus, agrees with this statement, but suggests groves of the future must incorporate the latest technology and improved varieties for citrus to remain strong in Florida.

While in many ways growers are producing citrus much like their grandfather’s generation, Barber argues the status quo will not sustain the industry. “Plain and simple, we have diseased trees here in Florida, and everyone is trying to figure out how to get longevity out of the trees they have in place,” he says. “We are not producing yields at the level we need to. So, as a company, we’ve decided to take a different approach.”

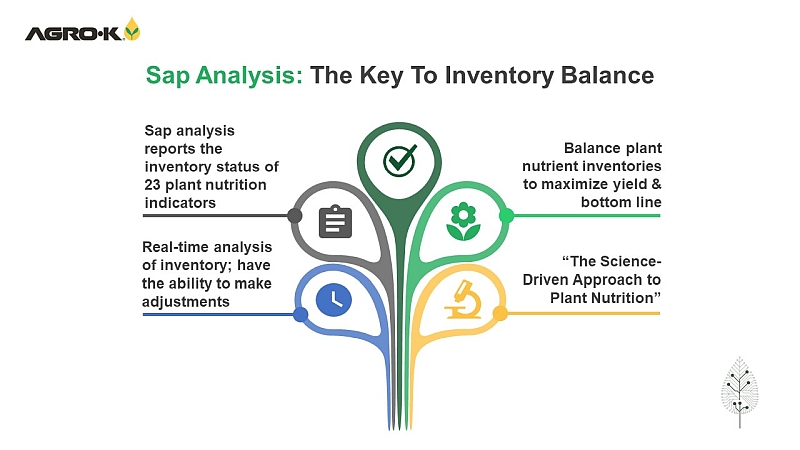

The approach is based on maximizing efficiencies in all aspects of production and building a detailed understanding and mapping what is happening in groves on an almost “real-time” basis. Barber likes to call it the “grove of the future” or a high-performance model.

“Our premise in this discussion about the grove of the future was trees and blocks would eventually succumb to HLB, unless we are very lucky,” says Barber. “Eventually, we would like to see a resistant tree, but that is too far off and we can’t wait on it.”

Going on the assumption that groves will have to be replanted, Barber says their future plan investigated how new plantings might be rethought. “We looked at other crops such as apples and olives that have gone to high-density plantings,” he says. “They basically re-engineered their operations or modernized them, you might say.

“We believe this a good opportunity to upgrade some of the mistakes that were made in plantings of the past. As we put in new blocks, we will try to do everything as correctly as possible. We will stay out of bad soils, plant the right genetics, and look at higher densities.”

Soul Searching

“As a company, we had begun discussing this concept before we even knew there was HLB in Florida,” says Barber. “We were looking at production levels not being where we needed them, so we began a discussion about how we move into the future and put new technology into use.”

Within the Lykes organization, the discussion soon turned into committees made up of employees responsible for production all the way through harvest and even accounting. “We started asking ourselves questions about what a high-performance model might look like,” says Barber. “After a lot of internal discussion, we got together and asked who would be the best people to answer these questions. I have to give a lot of credit to Dr. Bill Castle, of UF/IFAS, who helped us to put names to the areas of expertise in the research community. So, if we had a question about harvesting, we asked the person out on the cutting edge of harvest technology to help us find an answer. We did this with all our questions.”

Lykes Bros. Citrus’ Grove Of The Future

With the input of leading experts, Barber and his team put together a document, which laid out the plans for a high-performance model of Lykes Bros.’ long-range plan. Then the company hosted a two-day workshop with employees and some of the researchers involved to critique the document. “Out of that meeting came some tweaks to the document,” he says. “And, it is adaptable as new knowledge and technology comes on board.”

Seeking High Performance

So, what are the elements of the grove of the future? Barber says it is not just one thing. It impacts many aspects of the business of growing citrus and aims to achieve earlier fruit production out of trees utilizing the latest technologies like precision agriculture, GPS guidance, automated irrigation, GIS mapping, intense scouting, and mechanization in planting and harvest.

“Efficiencies is the word I’ve been using a lot lately,” says Barber. “We are striving for no wasted motion and no wasted inputs. We want to make sure we are putting out exactly the right amount of chemicals, water, and nutrients in a grove. This is where the utilization of precision ag is so important.”

While they have not settled on the exact high density-planting, Barber says this is an integral part of their future plantings.

Barber says new genetics are critical in the grove of the future. “When you hear people talking about new rootstocks and varieties these days, it is often about an HLB-resistant tree,” he says. “While this would be a huge bonus, it is not what I am focused on. I am looking for a tree that can produce early fruit yields and quality fruit. I am looking at a scenario where the tree might be in the ground for 12 to 15 years. We have to make our profitability out of the tree earlier, pull it out, and start over.”

In the grove of the future, scouting is going to be more important than ever. Already, Barber and his team are creating input maps of groves that illustrate precisely how trees react to fertilizer inputs over time. More than 1,000 soil and leaf analyses are taken in groves to set a baseline, then 40 samples are taken each month to follow trends in the grove.

He says they are using Google Earth to mark problem areas in groves for later scouting. They drive to the problem area and open Google Earth with their mobile device and mark their location. That’s a free technology that allows them to heighten their “footprints” in the grove approach.

Like many other growers, they utilize Tree-See technology, which Barber reckons has helped reduce fertilizer inputs by 15% to 30%. “Taking this a step further, using satellite technology and the detailed fertility maps we are building, we possibly could reduce fertilizer requirements by another 10% to 20%,” says Barber. “Some places may require more and some places less. The point is putting the exact amount in the right place.”

Scouting also will be important to better time insecticide applications. “My thought is we have kind of knee-jerk reacted to these disease issues,” says Barber. “I am not saying that is wrong, because it is better than doing nothing. But, we have to get back to using new science and technology to help preserve beneficial insects, using more of an IPM approach.”

Soil moisture monitors are deployed in the groves to alert when water is required for the trees. When water is needed, a signal is sent to the irrigation system. The system can be operated from anywhere in the world with an Internet connection.

Lykes Bros. currently harvests up to 40% of their crop with mechanical equipment. “I firmly believe that mechanical harvest is going to be a critical part of how we re-engineer groves to remain viable in the future,” says Barber. “With the labor situation uncertain as it is and how the cost of doing business is going up, mechanical harvest will have to be part of plans going forward.”

Barber says mechanical harvest is not an all-or-nothing proposition. There will be areas that need hand harvest and some more suited for mechanical, and in between, methods that can aid the hand labor like platforms that keep them from climbing up and down ladders all day.

The most important factor in the future of mechanical harvest is the approval of an abscission agent to loosen fruit from the trees. Currently, the agent CMNP is under review by EPA for a Section 3 registration.

Recently, Lykes Bros. has deployed mechanization in its planting with an ingenuous modification of a Whitfield pine tree planter to plant citrus trees. Getting back to Barber’s philosophy of efficiency, the citrus planter is capable of planting 3,000 trees per day. In addition, the traditional hand-planting method costs about $1.80 to $2.00 per tree, while using the mechanical planter runs 50¢ to 75¢ per tree.

While all these technologies are great and enhances a grower’s “footprint” in a grove, Barber says it is of no use if employees can’t run it. “Training our employees how to use these tools will be very important in the high-performance orchard of the future.”

Way Of Life

“The techniques we are suggesting here are nothing more than good farming techniques, utilizing the technology we will need to feed a growing world population,” says Barber. “This land is citrus land, and we need this industry to remain here in our state. When I retire, I want citrus to still be viable and an important part of Florida’s economy and landscape.”