Innovation, Teamwork Help Ferris Farms Make The Grade

Dudley Calfee

With every new occupation comes a learning curve. That certainly was the case for Dudley Calfee when he joined Ferris Farms in Floral City as its new general manager in 2007. Calfee came from a construction management background and had no previous experience in farming. But the equine-friendly location fit well for him and his wife Diane who both have a passion for horses.

The education process accelerated after his production manager was killed in a tragic accident only three months into the job. “We had a million and a half strawberry plants in the ground at the time, so the learning curve was steep,” says Calfee. “I learned a lot quickly and made a lot of mistakes. But, we have a great team here who pulled together and made this farm thrive.”

Calfee also attached himself to UF/IFAS professors like Joe Noling, Natalia Peres, and Oscar Liburd to help learn about growing in Florida. He got to know some of the strawberry growers to the south around Plant City who shared insights on successful production.

“The great thing about agriculture is everybody involved wants the other guy to be OK,” says Calfee. “That’s different than construction, which can be a little more cut throat.”

With a strong team of employees, the farm has continued to improve and grow with 85 acres of strawberries, 30 acres of blueberries, 25 acres of citrus, and Black Angus cattle.

“I can’t emphasize how important it is to have a strong team here from our managers to our pickers,” says Calfee. “They all care about this farm and we care about and have respect for one another. This encourages an atmosphere where we share ideas and feedback, which has improved the quality of what we grow.”

Leading, But Not Bleeding

“We like to stay on the leading edge of technology, not the bleeding edge,” says Calfee. “If we try something new, we want good science behind it, so we run trials with three replications and controls to collect data to prove something is working to improve our yields.”

New technology and practices are constantly being evaluated on the farm. “We usually have eight to 10 of our own trials going, and sometimes cooperating with UF/IFAS we can have up to 30 experiments running,” says Calfee.

One such experiment that has now expanded across all strawberries planted on the farm is the use of a Strawberry Advisory System (SAS) developed by Dr. Peres. The system was first tested on Ferris Farms starting in the 2008-2009 season.

The SAS gets weather data from a weather station located on the farm. It monitors leaf wetness duration and temperature, and that is used to calculate a disease infection risk for Anthracnose and Botrytis fruit rots, which are the two most important diseases affecting strawberries in Florida. The data is updated every 15 minutes. Once it determines there is a risk for one of the diseases in a certain location, it updates the information on the website (Agroclimate.org) and it also sends eMail and/or text message alerts to subscribed growers.

“By spraying only when weather conditions are favorable for those diseases, growers have been able to reduce the number of fungicides sprays by one third to half,” says Peres. “In the past, growers sprayed fungicides preventively to protect their crops because they didn’t know exactly when the diseases would occur.”

Calfee says the system has cut fungicide sprays in half on the farm. “We follow the model, but every once in a while, I’ll lose my nerve and spray when the SAS says we don’t need to,” he says. “But, those times are becoming less frequent because I am more confident in the system. It is a pretty miraculous thing to watch the system work.”

Quality First

Calfee says his harvest manager Lupe Fernandez and crew of pickers harvest some of the best quality strawberries in the state. Linda Gallant, who has worked as the farm’s office manager for almost 30 years also gives the berries a close inspection for quality.

“At first, I never thought I’d pick a flat of strawberries Linda would be satisfied with,” Calfee jokes. “Over the years, we have developed our harvesting techniques and quality control where we now have one of the best pack-outs in the state.”

A technology that has helped quality is Fresh QC tracking software. The system allows consumers to trace their strawberry clamshell back to the field and to the picker. While its original purpose is for traceability and food safety, it has helped identify areas where quality can be improved in the harvesting process.

“Our broker, Wish Farms, has done a fantastic job marketing our fruit, and their Fresh QC system has helped quality control,” says Calfee. “Once a picker harvests a flat, it has to pass our QC on the packing wagon in the field and ultimately the consumer gets to decide the quality of the berries.”

Consumers can comment on the good and bad of their strawberry purchase at FreshQC.com. This brings accountability for quality harvest to a higher level. “I’ve found that most times the consumer is right,” says Calfee. “Miss Jones in Boston might go to the website and say her strawberries tasted watery. And, sure enough, I go back and look and find those were picked the day after a big rain. It is not always the pickers fault, sometimes Mother Nature can cause problems, or it is a decision by management to harvest a field at an inopportune time.”

Photo by Frank Giles

The Methyl Bromide Void

Calfee had access to methyl bromide use in his strawberry production for one season, so he says in some ways he feels fortunate he came to learn pest control without any preconceived notions stemming back to the void left as methyl bromide was phased out. But, he says pest control can be a challenge, especially weed control in the absence of the fumigant.

“We put out a pre-emergent herbicide when we build our beds, but that doesn’t carry you too far before it is gone,” he says. “Right now, all we really have to control weeds is hand labor. So this is an area where we need help.”

Calfee is the chairman of the Florida Strawberry Growers Association’s research committee. He says the committee has directed a sizeable amount of new funds toward weed control research in the past year to find solutions.

For fighting disease and other pests, two drip tapes have been added per bed to better distribute methyl bromide alternatives. “Working with Dr. Noling, we have pretty much settled on Telone C35 (1,3-Dichloropropene and chloropicrin, Dow AgroSciences) as our soil fungicide and nematicide,” says Calfee. “Dr. Noling has been invaluable helping us test and learn about new products.”

One plus coming out of the phase-out of methyl bromide has been extending the use beds into two seasons because in-line fumigation is possible. “We try to get two seasons from the tape and plastic,” says Calfee. “One field, we tried to get three seasons, but it’s nearly impossible to remove the plastic after it had been there so long. We’ve settled on two seasons.”

All workers at Ferris Farms keep an eye out for problems. The flags mark a small outbreak of spider mites, which were due for a spot treatment soon after the discovery.

Photo by Frank Giles

100 Sets Of Eyes

While Calfee is always testing new technologies, he says the human resource is critical in keeping a pulse of what is happening on the farm. “We encourage our workers to be alert to how plants are looking in the field and report if they see disease or pests, so we can go out and spray and keep it contained,” he says. “We have 100 sets of eyes on this farm on the lookout for problems or opportunities. So, in a way, it is like precision agriculture gathering real-time visual information.”

One example of encouraging worker interaction is a bounty placed on Japanese beetles in the farm’s blueberries. The first five workers who bring in a live beetle get a $5 reward. This was done after the beetles unexpectedly caused a problem one season during the harvest period and lets management know when — or if — the pests arrive again in the current season.

Stewards Of The Farm

The application of innovative technology has allowed Calfee to reduce inputs, while growing yields and quality. Currently, he is installing automated controllers on the irrigation pumps to more precisely control water usage. The farm also follows BMPs to manage nutrients levels.

“We are very careful about the nutrients we put out,” says Calfee. “Nobody wants to put out more fertilizer than they have to, so we have a very rigorous soil, leaf, and media sampling program to fine tune our applications.”

Ferris Farms was recognized for its stewardship by receiving the Commissioner of Agriculture’s 2013 Ag-Environmental Leadership Award. “We care about this farm and its future, so that we take care of it only comes natural,” he says.

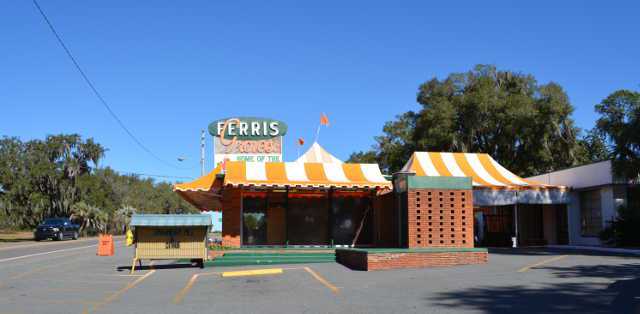

Peddle By And Grab A Shake

Ferris Farms’ retail market is located on Highway 41 and only a hundred yards or so from the Withacoochee State Bike Trial, which is ridden by 300,000 cyclists per year. To tap into the great market potential, Ferris Farms paved a path from the retail store to the trial and put up a sign inviting bikers to swing by and have a strawberry milkshake. The market also ships and sells fresh citrus and sells strawberries, blueberries, and Black Angus cattle raised on the farm, along with other regional gifts and fare.

Photo by Frank Giles