Metalized Reflective Mulch a Bright Spot for Citrus

Bob Adair, Florida Research Center for Agricultural Sustainability Inc., inspects a tree planted on metalized reflective mulch. After more than four years, the mulch is still intact.

Photo by Frank Giles

For 30 years, Bob Adair has tested novel ideas in producing citrus at the Florida Research Center for Agricultural Sustainability Inc. in Vero Beach. He is particularly excited about a recent project testing the viability of using metalized reflective mulch in citrus plantings.

While plasticulture is not new in vegetable production, it is a novel idea in citrus. Plasticulture in vegetables began in the mid-1950s. Today there are as many as 2,500 square miles of agricultural lands that use plastic mulch across the globe. Using a highly reflective surface came a little later, and vegetable growers have been successfully using it to deter pests.

Adair and his co-investigators from UF/IFAS wanted to test the hypothesis that metalized reflective mulch could deter Asian citrus psyllids (ACP) in new plantings and, thus, keep HLB levels lower in young trees. The idea came from Phil Stansly, a longtime entomologist with UF/IFAS. Fellow UF/IFAS entomolgist Scott Croxton also worked on the project because of his experience using metalized reflective mulch to deter whiteflies in tomatoes.

Adair’s son Matthew has done a lot of the fieldwork and data collection over the life of the project, which is now in its fourth year. The study covers a 10-acre grove and compares three systems — bare ground, compost, and metalized reflective mulch — each laid out in a checkerboard pattern with 100 trees in each plot and replicated five times for each treatment.

‘Ray Ruby’ grapefruit were planted on sour orange rootstock. All treatments received the same post-plant horticultural practices for sprays, fertilization, and irrigation. All applications were made in accordance with UF/IFAS recommendations.

“This was an exhaustive and vigorous layout consisting of 1,500 trees,” Adair says.

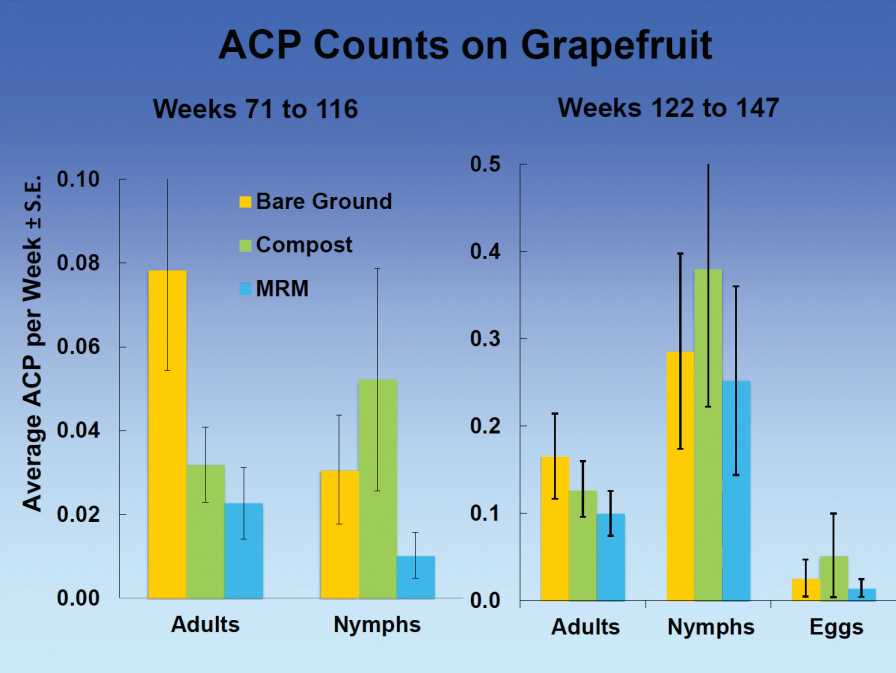

The data shows that metalized reflective mulch deters ACP from new plantings. Adult and nymph counts were lower in the metalized reflective mulch planting when compared to bare ground and compost. The reduction was significant, especially early on when more mulch was exposed to the sun. Adair says those differences become less as the tree canopy grows and covers the mulch area; but even then, the ACP numbers remain lower than in bare ground and compost.”

The 6-foot-wide metalized reflective mulch maintains a foot on each side tucked in the ground to secure it, leaving a 4-foot surface exposed.

Photo by Bob Adair

Good Bed Prep Critical

Proper mulch installation is important to its effectiveness and longevity. The mulch used in the trial was Shine N’ Ripe, manufactured by Imaflex. It is heavy-duty, 3-mil, totally impermeable film coated with highly reflective aluminum that reflects more than 90% of solar radiation for three years or longer.

“The key thing we learned is the importance of putting out the material correctly in the first place,” Adair says. “We were not the first to do this and learned from others’ mistakes. Good ground preparation is one of the most important tasks of installation.”

Proper preparation includes getting rid of as many potentially germinating weeds (nutsedge in particular) as possible. This is not easy in Florida, but it’s an important step. Adair’s team tilled the seed-bed for the metalized reflective mulch extra times and applied additional herbicide applications and a burn for hard-to-till weeds. He then used a rotavator, followed by a roller, to firm up the bed prior to laying down the metalized reflective mulch.

The metalized reflective mulch was laid under the supervision of Croxton using a Kennco bedding machine. The goal is to lay the film out as flat as possible. The film is 6-feet wide, with a foot tucked in the ground on each side, leaving a 4-foot surface. In future plantings, Adair plans to use an 8-foot film to increase the surface area to 6 feet.

“Because it is impermeable film, you don’t want to have dips in the plastic that would result in puddling of water after rains,” Adair says. “We ended up with an amazingly smooth and flat surface area.”

The holes in the film were cut (in a plus pattern) with box cutters to avoid stretching or tearing the plastic. Holes were dug, trees planted, and film laid back over the area.

“We were again surprised how little trauma was done to the film in the laying and planting process,” Adair says.

Irrigation tubing was set on top of the film and utilized two drip emitters (2 gallons per hour) tucked under the plastic on the north and south side of the trees.

UF/IFAS entomologist Phil Stansly shows the growth difference between trial plots of bare ground (left) and metalized reflective mulch (right) at 3.5-year-old citrus trees.

Photo by Bob Adair

Surprising Results

While the metalized reflective mulch trial primarily sought to find if the practice would reduce ACP populations in young plantings, data collected on tree growth and yield of trees showed surprising results.

“We were looking to deter the ACP, but what we really observed was the tremendous growth of trees under this metalized reflective mulch (MRM) system,” Adair says. “The trees took off, and the older they got, the faster they grew. Looking at two different time periods (19 months and 28 months), we saw a tremendous increase in canopy growth with MRM.”

The trunk caliper size illustrated the growth at 165 days after planting. The MRM trees had a 57.6% larger caliper than trees planted on bare ground. Fruit yields were double at the 21/2-year mark when compared to bare ground, and nearly triple a year later.

“We looked at fruit size and were pretty excited to see less smaller fruit in the MRM versus bare ground,” Adair says. “This would suggest we have less HLB in the MRM. Equally interesting was the fact we saw larger fruit in the MRM planting in the same type of distribution.”

Adair used an optical fruit sizing machine developed by Brian Boman, an agricultural engineer with UF/IFAS (retired), to size and weigh each fruit from 80 trees, in each treatment, to collect a large amount of meticulous data.

“Another exciting surprise was the realization that the MRM was protecting roots from Diaprepes [root weevils] when we scouted and found lower populations under the mulch,” Adair says.

“The adult females lay eggs between the leaves. They hatch seven to 10 days later, and the larvae fall to the ground. Those that land on the MRM desiccate or get preyed upon and die.”

The mulch also appears to be protecting roots from potential systemic herbicide damage. And, while no data was collected on this, Adair says there are numerous studies that show the reflection of infrared light reduces soil temperatures and creates a more habitable rhizosphere for roots to grow.

Data points show that metalized reflective mulch reduces psyllid counts in young trees and dramatically increases yields compared to bare ground and compost. Graphic courtesy of Bob Adair

Economics

The compost applications added an additional $75 per acre compared to bare ground, while the additional herbicide treatments and other applications brought the total MRM costs to $706 more per acre than bare ground.

Annualized over three years, the cost of the MRM is $235 per acre, and over four years, the cost is $176 per acre.

“When we picked the first crop at 21/2 years old, the yield advantage was striking,” Adair says. “But what was really exciting was when we deducted the costs for installation and producing the fruit, the MRM treatment was the only one in the black (when annualized over four years). With the following crop, the return with MRM increased to $555 per acre, and both other treatments lost more than $1,200 per acre.”

An added benefit — because of the plastic cover — the system requires less fertilizer, water, and herbicide after planting the trees.

“We are in the early-adaptors stage of this right now because there are only a few MRM plantings here in Florida, California, and Brazil,” Adair says. For growers who are considering whether to try this, Adair says, “I can tell you what we saw. Trees are going to grow faster, and you are going to have more fruit with earlier production and less HLB. And if you do this in a whole block (not the checkerboard layout like the trial) and do low-volume sprays on your perimeters, it will be even more effective at deterring ACP and reducing HLB.”