New Technology Helps To Solve The Berry Mechanization Challenge

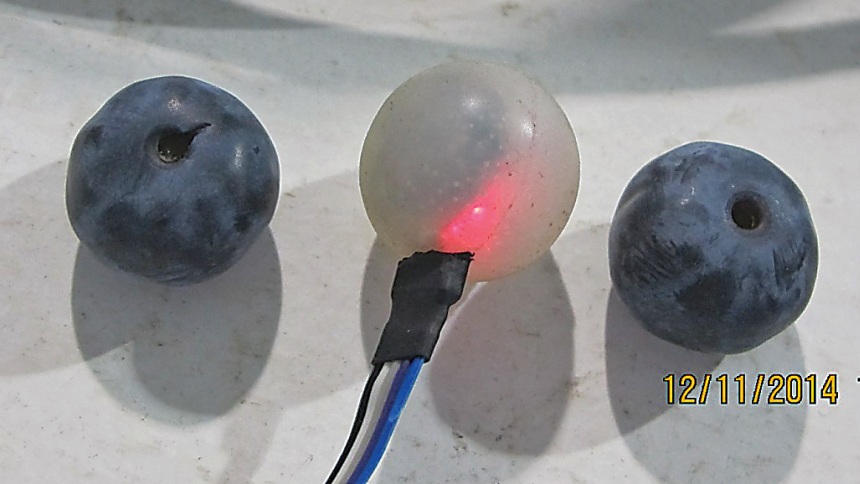

The BIRD device is a wireless data-logging sensor that is similar in size and shape to a blueberry. (Photo credit: Charlie Li)

Blueberry production is a billion-dollar business in the U.S. Although the industry grows every year, a key stumbling block to mass production is labor. More than 70% of fresh-market highbush blueberries are harvested by hand and the issue of labor availability continues to become a greater concern.

A research team from the University of Georgia, as USDA-Agricultural Research Service (ARS), Michigan State University, University of Florida, Penn State University, Washington State University, North Carolina State University, Oregon State University, and Mississippi State University hopes to solve the challenge of increasing production while making mechanization gentler and affordable.

“During harvest, postharvest handling, and transportation, blueberries will invariably interact with various machine parts or contacting surfaces. These interactions will create bruises and reduce fruit quality,” Changying “Charlie” Li, associate professor of engineering at the University of Georgia says. “In the past, these potential impacts created by mechanical handling could only be evaluated by assessing the quality of blueberries after the handling process due to the lack of effective sensing tools.”

Lialong with Fumiomi Takeda, lead scientist at the USDA-ARS Appalachian Fruit Research Station in Kearneysville, WV, worked to develop the Berry Impact Recording Device (BIRD) as part of a USDA National Institute of Food and Agriculture (NIFA) Specialty Crop Research Initiative (SCRI) project. Li and Takeda’s research also had support from the U.S. Highbush Blueberry Council to improve upon the first-generation BIRD Sensor.

A Sensor The Size Of A Berry

This BIRD device is a wireless data-logging sensor that is a similar shape, size, and weight of a blueberry. This sensor rides along with blueberries through the handling process from mechanical harvesting, packing, and transportation to measure the impact.

Li says the concept of impact sensors is not new. However, none are small enough to use to measure the impact of harvest on small fruit. This is precisely why the BIRD sensor was developed. The sensor measures the impacts the blueberries experience through an accelerometer and microprocessor in the device. The second-generation BIRD sensor has a diameter of 21 millimeters and weighs 6.9 grams.

“Previous studies showed that bruise damage developed on as much as 78% of mechanically harvested highbush blueberries, making the fruit unacceptable for long-term cold storage and fresh consumption,” Li says.

Damaged fruit also opens the skin to postharvest decay and organisms, Takeda says.

“Our research effort is directed at relating these impacts to fruit firmness and bruising resulting from a fruit being hit by vibrating rods when it lands on a hard surface,” Takeda says. “Eventually the BIRD technology can be used to predict the degree of quality loss from the impact values it gathers. This means it offers a technology to measure internal bruise damage rapidly and without destroying the fruit.”

The BIRD device can measure the impact of harvesting and transport on soft fruit. Researchers hope to use these sensors as new harvesting equipment is developed. (Photo credit: Charlie Li)

Research Might Pay Off Hugely

Another stumbling block to growers initiating mechanical harvesting of berries is the price of equipment. Part of Takeda and Li’s research is also developing affordable harvest aid equipment.

Li and Takeda are among a group of researchers developing an affordable harvest-aid system and sensor technologies with the help of a SCRI grant. Li and Takeda are taking a multi-disciplinary approach to improving harvest efficiency and postharvest handling of fresh blueberries.

Takeda says the team wants to develop “an affordable self-propelled harvest aid system with ergonomic design that can improve harvesting efficiency more than 10 times compared with hand picking, with better fruit quality, and reduced ground loss (of fruit).”

Paring this new harvest-aid technology with a second- or third-generation BIRD device, researchers and growers will be able to better understand the stress fresh blueberries undergo with these new harvest devices.

Takeda and Li hope this research will reduce harvesting fatigue, ground losses of fruit, and fruit damage, and above all, be affordable for all growers. The research team is also studying genotypes of blueberry varieties to find the best cultivars suitable for semi-mechanical harvesting.

“This has been addressed partially with the recent development of novel highbush blueberry cultivars with crisp-textured (“crispy”) berries, i.e., fruit with qualitatively firmer flesh and/or more resistant skin,” Takeda says.

Takeda says microbial contamination is another concern for growers and consumers.

“We will investigate the potential microbial contamination in both blueberry fruit and mechanical harvesters and determine critical control points along the harvest and postharvest chain,” Takeda says.

Grower Driven

The objectives of this project were identified and developed with input from blueberry growers, packinghouse operators, equipment manufacturers, and Extension agents, Takeda says. In fact, in a recent producer survey, the goals were affirmed.

“Reducing labor and harvest cost is one of the most pressing issues facing blueberry growers, and growers are eager to adopt new harvesting technologies that can reduce cost, improve efficiency and fruit quality, and reduce the fruit losses,” Takeda says.

Ultimately, Li says these projects can’t be successful without grower and equipment manufacturer cooperation. These developments are designed to help the highbush blueberry industry become more sustainable and profitable, he says.

“We strongly encourage growers to be more engaged in the project through workshops and field day demonstrations. We appreciate the support from the growers and we need their continued support,” Li says. “That is the strongest motivation for us to do good work.”