How These Produce Growers Handled COVID-19 With Success

This past year has obviously been a challenging one due to the COVID-19 pandemic. We wondered what growers had done to get through this year, so we surveyed a number of you around the country — with one reply from a grower in Europe — to learn how you handled your particular situation.

We posed a few questions, asking what issues the pandemic might have caused for your business, what strategies you may have implemented that proved effective in dealing with it, and what other related challenges you may have faced. Here is a sampling of the answers we received.

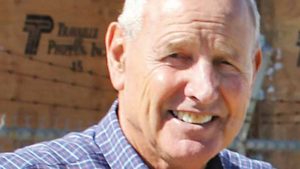

Don Cameron, Tree Nuts, Wine Grapes, and Vegetables, Vice President and General Manager, Terranova Ranch, Helm, CA

Our strategies changed rapidly and early when COVID-19 hit our area. By mid-March, we understood that this was serious, and our worker safety and health was our No. 1 issue. We immediately implemented rules requiring masks for all employees, social distancing where possible, hand sanitizer, throw-away plastic foodservice gloves for all touch points, such as ice machines and fuel dispensers.

We changed work schedules so that fewer employees were congregating in the morning when work started. The real challenge we faced was the education and awareness of the threat of COVID-19 and the importance of following procedures at work and at home. We had worker safety meetings that concentrated on keeping our workers and their families safe and healthy.

2020 turned into the year of uncertainty. In the first half of the year, we had no idea if our buyers would honor contracts, if demand would remain constant, or if the processors could remain COVID-19-free to receive our crops. The other question was the ability to have the labor available to harvest the crops. My goal was to have a break-even year, anything above that was a win. Now that we are in the last quarter of the year, it’s apparent that we succeeded to have a decent year after all. We feel fortunate that we are an essential service and have continued to work to provide food.

David Doll, aka “The Almond Doctor,” General Manager, Rota Unica, Evora, Portugal

As in other areas, agriculture was deemed a critical industry, and we were able to function at a near-normal level. With most of our focus on developing new orchard blocks, we were heavily reliant on vendors and the supply chain to hold up with the various shutdowns that were occurring across Europe. As such, most of our issues have been delays in receiving PVC, stakes, trees, etc. The only way we were able to manage this was to utilize multiple vendors to source the various products. This helped some, but I think I learned more about patience in 2020 than anything else.

The ongoing issues with COVID-19 have created challenges for our team members and their families. Schools randomly shut down, and the children are at home requiring supervision. Family members could fall ill and require care. This ongoing risk means that we may be running shorthanded at any position within the company at just about any moment. Foreseeing this back in March, we hired a “utility player,” someone who could help manage projects on the farms and assist with various admin functions. This position stepped in and helped complete various tasks as needed. After COVID-19, their role will expand as they now have a better sense of both field and administrative operations.

We are emphasizing continuing education for our team members. Most meetings have been put on hold, and there has been very little professional development. Since many of our members are new to perennial crop agriculture, they require training to aid them in becoming better at their positions. We increased our budgets to accommodate an extra training session in 2021.

We are emphasizing continuing education for our team members. Most meetings have been put on hold, and there has been very little professional development. Since many of our members are new to perennial crop agriculture, they require training to aid them in becoming better at their positions. We increased our budgets to accommodate an extra training session in 2021.

Jon McClarty, Stone Fruit and Grapes, President, HMC Farms, Kingsburg, CA

2020 was very much and is still continuing to be a challenge. We are currently (late-Oct.) finishing up marketing plums but are still in the thick of the table grape harvest. One of the difficult things to deal with in farming are the changes you need to adapt to and the surprises that necessitate those changes. 2020 was full of planning for surprises and challenges, much more than a usual season. The guidelines on how to best approach COVID-19 while being an essential business seemed to be a moving target, and there was a lot of concern early on that we weren’t going to be able to harvest our crop. We started off very diligent in our approach to COVID-19, requiring masks in the production facilities, re-emphasizing best hygiene practices, and doing contact tracing with confirmed or suspected cases.

HMC Farms President Jon McClarty and Vice President Drew Ketelsen of Kingsburg, CA. (Photo by David Eddy)

As difficult as the production side of the equation was, the market disruptions for our company were just as challenging. Our food service grape import program was devastated, and the early California stone fruit market was one of the most peculiar we have seen in a quite some time.

Just as things started to become a little more normal, though still far from normal, the wildfires started. This made grape harvest much more challenging and, ultimately due to the decreased solar radiation, slowed maturation to a crawl. We are now two or more weeks behind where we should be in a normal year, and consequently we believe a large portion of red grapes will not be able to be harvested this season, as they are unlikely to color.

Though 2021 is only a bit away, we are still focused on getting through the 2020 season. Without any specifics, I would say a priority for 2021 would to be to expand the margin of error so we can better handle the unexpected issues that seem to be occurring with more regularity.

David Phippen, Almond Grower and Processor, Travaille and Phippen, Ripon, CA

The fear of a COVID-19 outbreak in our small, family-owned processing facility created a heightened awareness of how serious this threat was to our daily production needs. We followed the many suggestions that common sense would confirm might lead to a good outcome.

Impressing upon our valued workers, who are typically very social, remained our best defense as well. We rewarded them with bonus money as we asked them to practice social distancing at home and in their personal lives. The bonuses seemed to impress upon them the serious threat and our serious “ask” of them to change their social habits.

We also purchased fogging equipment and exercised to the greatest extent possible the cleaning of all surfaces, especially touch points throughout our facility. Again, showing them the serious threat we believed this to be seemed to help. Sort of walking the talk, so to speak.

Phil Schwallier, 2018 Apple Grower of the Year, Retired Michigan State University Extension Agent, Sparta, MI

It gave us an uneasy feeling of not being able to open our farm market, but this season has been outstanding for us. The weather has also been great. Our apple crop was excellent with large fruit size, beautiful color, nice finish, and good yields.

Again, we were concerned about getting labor to pick, but we now have plenty of labor. The major issue we’re having is dealing with another set of papers to fill out with workers. (Are you sick? Sign in every day indicating you’re not sick.) Another was getting gloves and masks for everyone. However, we ran harvest and the farm market with no problems — so far.

Wes Asai, Almonds, Turlock, CA; American and Western Fruit Grower Columnist

The biggest change I noticed as both an almond grower and independent consultant was the absence of direct contacts and networking with industry associates. Examples would include no person-to-person meetings, no speaking at or attending grower meetings, no industry meetings, no professional society meetings, and no trade shows. I miss these opportunities to learn the most current information and to make business contacts.

Early on, finding masks and sanitizer for myself and my employees was difficult. Other challenges included finding additional labor and being able to get continuing education hours for licenses and permits. Our top priority for 2021 is to try to get back to business as usual as soon as possible. With all the uncertainty, it is still hard to predict when this will be. Simple things, like dropping by the chemical supplier to pick up a couple sacks of fertilizer, going by the tractor repair shop, or visiting the Ag Commissioner’s office, require added time, special procedures, or waiting in lines.