New Tech Helps See Whole Picture of Table Grapes

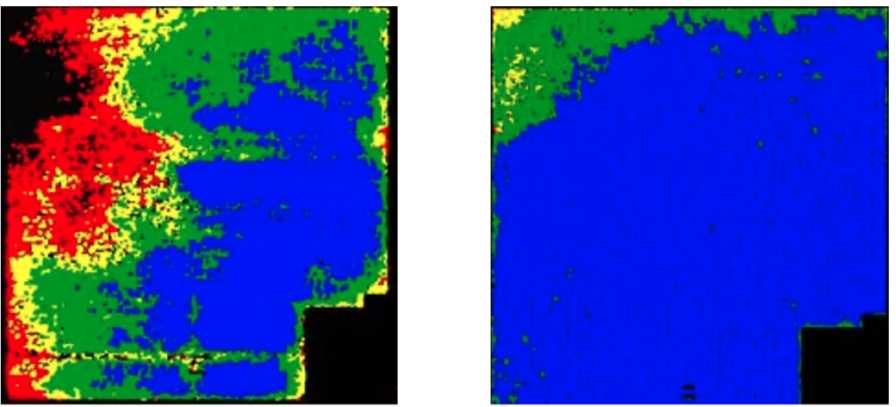

The addition of an irrigation set in an underperforming area helped increase table grape yields from less than 30% the yield of adjacent blocks to more than 80%.

Photos courtesy of Ceres Imaging

Fowler Packing, the Fresno, CA-based grower/packer/shipper of table grapes, citrus, and nuts, had long known that a piece of its acreage was underperforming. How to address the issue, however, was never as clear-cut.

Prior to 2017, the western part of Fowler’s ranch, where table grapes are grown, was regularly weaker than the rest of the block. Canopy in some areas resulted in only about 25% shade coverage during the growth season, while the remaining areas of the ranch were full-row coverage. Yields, according to Senior Irrigation Systems Specialist Kyle Moeller, were minimal, with small berries, weak bunches, and limited crop being sustained on each vine.

Prior to the table grapes, tree fruit had been grown on the land, resulting in the same stress and production woes.

“Our main theory was it was just a soil issue, primarily being sandier than the rest of the ranch,” Moeller says. “But it was hard to put a firm number on the overall extent. As you’re walking a block, it’s hard to visualize how much area is truly being affected. We originally thought this issue was on a smaller scale.”

That is, until Fowler Packing used flight imagery to get a better read on its problem.

EYE IN THE SKY

Ceres Imaging, based in Oakland, CA, connected with Fowler Packing in 2017. Founder Ash Madgavkar had launched the company three years earlier, hoping to use high-resolution, multispectral imagery to assist drought-hindered California growers with their irrigation issues.

“One of Ceres’ managers was basically making field calls, trying to see if growers were interested in their flight imagery,” Moeller says. “We decided to do some preliminary work in our citrus department and eventually moved Ceres into covering more ranches. Initially, it was primarily only ranches that had issue blocks or regions that we wanted to start looking at overall extent and making some initial conclusions from their platform.”

The Ceres technology involves capturing flight imagery during peak daylight hours and under weather conditions that minimize distortion from shadows and cloud cover. Highly sensitive, custom-built cameras detect minute changes in the multispectral range. The company’s in-house remote sensing experts assess the imagery, passing it through multiple checkpoints before delivery in the Ceres Imaging app within 48 hours of the flight. Growers such as Fowler Packing can access their data on a mobile device, tablet, or desktop computer.

“We were able to really see from the thermal imaging the amount of heat being generated from the direct sunlight on the problem area,” Moeller says. “Using the NDVI (Normalized Difference Vegetation Index), we were able to see the variation in canopy size in comparison with the rest of the block, which was extremely weak. Initially, Ceres said they were unsure of the exact issue but could see the west edge of the ranch was weaker and struggling. It was our team, in talking with Ceres, that figured the main culprit was the water-holding capacity within the soil structure, which would need to be combated first.”

Fowler Packing decided to construct a separate irrigation set on its ranch to irrigate the problematic region.

“Our irrigation strategy has changed because of the imagery as well as soil moisture devices placed in each block, with one monitoring the weak zone directly,” Moeller says. “We irrigate based on evapotranspiration and soil moisture data, which allows us to see what depths have water available to the plant. Upon installation of probes, we could see water draining through the root zone at a faster rate than the rest of the ranch, which causes us to add a supplemental irrigation several times in the week to keep water available to the plant.”

PLAYING CATCH-UP

The project took multiple years. Its effect is ongoing, Moeller says. Year one involved seeing the images for the first time and discussing with Ceres what they could be indicating. In the off-season the irrigation system was adjusted. A new irrigation set that would supply water directly to the weak area was installed.

“From there it took several seasons to bring the vines out of the severe stress they had been under since planting,” Moeller says. “Currently, they are getting closer to being the same as the rest of the block in terms of canopy and yield.”

Despite little prior experience with flight imagery, Fowler Packing quickly adapted to the technology, with Ceres’ help.

“When it comes to learning curves with the software, these guys are pretty good,” Moeller says. “I would say we are still learning what to look for and how to understand individual images correctly, but there is not an exact science in my mind for what an image is showing. You can look at trends to get some idea, but you won’t know exact problems until visiting the field and going to the point you saw the issue.”