How Canopy Structures Can Affect Sweet Cherry Productivity

Greg Lang

We have previously explored orchard cover technologies to modify climatic risks in sweet cherry production, such as rain-cracking and spring frost. Now let’s examine tree canopy training systems to modify growth, optimize fruit quality, and facilitate labor efficiency.

Sweet cherry trees naturally exhibit acrotonic growth, which means annual shoot extension and branching occur predominantly and most vigorously in the upper part of the canopy. This yields a tree architecture that captures the most light in its upper regions and heavily shades lower regions, which is a good strategy for competing with other trees in a forest.

Of course, this is very inconvenient for managed fruit production, requiring labor-inefficient ladders for most pruning and picking, and powerful air-blast sprayers to deliver pesticides. The goal in modern orchards is to develop smaller trees that promote good light interception and distribution throughout the canopy, to yield uniform, high quality fruit more accessible from the ground.

Using Rootstocks To Control Vigor

One key for achieving smaller trees is the use of vigor-controlling rootstocks. The NC-140 Regional Research Project “Improving Economic And Environmental Sustainability In Tree Fruit Production Through Changes In Rootstock Use” coordinates research trials of new tree fruit rootstocks in multiple locations across North America.

The NC140 cherry research trials from 1987 to 2007 evaluated new hybrid rootstocks that conferred previously unseen levels of precocity (ability to begin fruiting at a young age) and variable levels of tree vigor (or dwarfing). These led to the commercial release of the Gisela (Gi) rootstock series: Gi.3 (dwarfing, 30-45% of standard), Gi.5 (semi-dwarfing, 50-65% of standard), and Gi.6 and Gi.12 (semi-vigorous, 75-90% of standard).

Initial research and grower trials with these rootstocks resulted in impressively early and high yields, but disappointing fruit size. Physiological studies and increased grower experience subsequently have led to a better understanding of how to provide timely nutrients and water to these smaller root systems, and how to prune annually to improve leaf-to-fruit ratios for a better balance between yields and fruit size.

Over the last 10 years in our various Gisela rootstock-based cherry research trials at Michigan State University, we routinely achieve fruit sizes across dozens of varieties that range from 25 to 35 millimeters in diameter and 10 to 16 grams in weight. Clearly, small trees can yield large fruit!

Productivity And Canopy

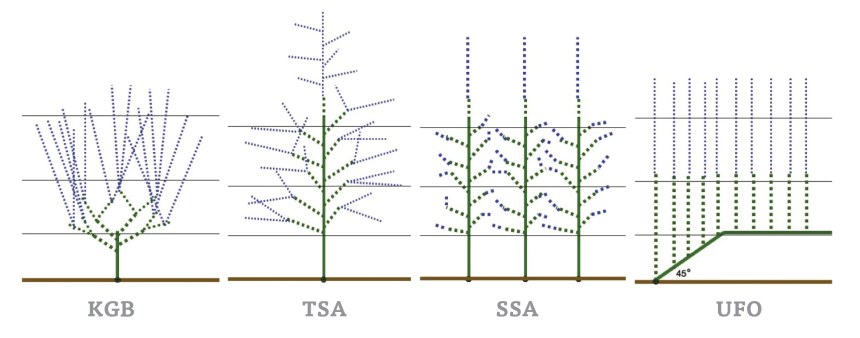

In 2010, an NC140 sweet cherry regional research trial began examining the interaction between four distinct canopy architecture/training systems (see figure) and these new rootstocks that confer early, high productivity and modulated vigor.

The four architectures were: a somewhat traditional central leader dubbed the Tall Spindle Axe (TSA); a trellised, very high density central leader, the Super Slender Axe (SSA); a multiple leader bush known as the Kym Green Bush (KGB); and a trellised, multiple leader “fruiting wall,” the Upright Fruiting Offshoots (UFO). These canopy training systems (plus several others) are described in detail in a new publication, “PNW 667 — Cherry Training Systems,” a multi-institutional electronic Extension bulletin developed by Oregon State University’s Lynn Long, myself, and Stefano Musacchi and Matthew Whiting, both of Washington State University. It can be downloaded free.

It also has been adapted as a free application for tablet computers, available for iPads or Android-based tablets.

Cherry training systems in NC-140 Trial: The interaction between four canopy training systems — Kym Green Bush (KGB), Tall Spindle Axe (TSA), Super Slender Axe (SSA), and Upright Fruiting Offshoots (UFO) — and new rootstocks are being compared in this NC-140 trial. (Graphic credit: Greg Lang)

Better Light Distribution

The four training systems in the study share several unifying objectives. The first is to change the acrotonic growth habit of sweet cherry, albeit in different ways, to improve light distribution lower in the canopy. This is promoted by developing more than 5 to 6 secondary shoots from the leader seasonally during establishment; more secondary shoots initiated each spring helps maintain their vigor uniformity, minimizing dominance. Second, this rapid canopy development takes advantage of rootstock-induced precocity and improves early yield potential.

The target is for the orchard area allotted to each tree to be filled within three years, and the canopy fruiting volume (vertical canopy development) completed within five years. In Michigan, the early yield potential was highest for the SSA system on Gi.3 for years two to four. However, as the canopies matured, the highest yields shifted to the TSA and UFO systems on Gi.3 and Gi.5 in year 5; in year 6, the UFO/Gi3 was highest, followed by SSA/Gi3, then UFO/Gi5. Detailed analysis of the rootstock by training system yields and fruit quality will be addressed in a future column.

A third unifying objective is to develop a minimal permanent trunk, denoted by the solid green line in the graphic above for the TSA and SSA central leaders, the KGB stump, and the UFO cordon. From this permanent wood, temporary fruiting structures are developed, denoted by the dotted lines in the graphic above. A fourth common objective is the annual renewal of a portion of this fruiting wood, which is one of the keys to producing high quality fruit over several decades. While the trunk ages, leaves and fruit buds are maintained in a youthful state. A fifth objective is for the majority of orchard work to be conducted from the ground, using short ladders or mechanized platforms only when necessary.

These training systems have different initial investment costs, establishment and maintenance costs, early versus mature yield potentials, efficiencies for picking, etc. The digital guide noted above can provide many of the seasonal details for establishing each system and matching to appropriate rootstocks in various climates. In the next column, some of these different economic factors and the NC140 trial results thus far will be examined.