Peach Tree Precision Growing Into a Thing of Beauty

Dario Chavez wants to walk the same walk that Greg Lang had for so many years, only in-between fruiting walls of a different type of stone fruit. Lang, the recently retired Michigan State University Professor of Horticulture, trailblazed the evolution of canopy architecture and high-density planting systems in sweet cherries. He frequently wrote about his work as a columnist with American Fruit Grower.

Chavez now writes a similar stone fruit column, but his specialty, as an Associate Professor of Horticulture at the University of Georgia, is peaches.

“He kind of revolutionized cherries,” Chavez says of Lang, a Georgia native himself who knows a thing or two about peach trees as well as cherry trees. “It’s been exciting to see his results.”

Can Chavez similarly transform peach growing in the South? It will be more difficult, he admits, because of the heightened disease pressure in the steamier states of Georgia, South Carolina, Florida, and Alabama, but at age 40, he is off to a good start. His latest work — on three-dimensional, high-throughput phenotyping of peach tree architecture using terrestrial laser scanning — follows through on what Lang had written in his farewell column in December of 2022:

“The general direction of future orchards is crystal clear to me: simplified fruiting walls. For all the major tree fruits, we now have the combination of various training techniques and an increasing selection of vigor-modifying rootstocks for everyone to achieve simplified, narrow, planar walls of fruit. … I will enjoy watching, albeit from the sidelines, the continuing rapid advancements in orchard technologies that take advantage of these highly structured, narrow fruiting walls. Even as we may worry about the initially intensive labor to develop, maintain, or renew precise matrix-like canopies, the increasing capability and decreasing cost to electronically map and image those canopies is leading to so many future technological applications that may reduce those labor concerns down the road! … These image and fruit-leaf data sets will eventually guide robotic implements for spraying, pruning, fruit and leaf thinning, and harvest that would be impossible to imagine a decade ago in a three-dimensional canopy.

Of course, some people have bigger imaginations than others. Dario Chavez is one of those individuals.

HIGH DENSITY, HERE WE COME

Chavez desires nothing less for peach growers than what their apple counterparts have been enjoying for decades now — high-density planting systems.

“We want to be able to produce fruit in the most efficient way,” Chavez says. “What I mean by that is we’re not in the business of growing trees. We’re in the business of producing fruit. You look at apples, and the apple system is waaay ahead of us as peach producers.”

Unfortunately, current peach production in the traditional open-vase training system is far from efficient. Manual labor must be applied across most activities, and labor costs have turned exorbitant. At the top of that expense list is pruning.

Dario Chavez

“That gives you an idea as to why we need precision ag,” Chavez says.

To date, precision ag has largely been a moot point in the peach orchard. The reason peach growers have lagged behind apple growers in terms of high-density plantings is the absence of dwarfing rootstocks.

“We know there is an effect from rootstocks, and that’s how the apple revolution happened, because they found dwarfing rootstocks,” Chavez says.

Fortunately, that landscape has changed. “We actually have the dwarfing rootstocks now in peaches,” Chavez says, largely referring to peach-plum hybrid MP-29. “We’re very excited about that.”

MP-29, which has shown significant disease resistance, produces about 40% of the canopy volume compared with high-vigor Guardian rootstock, which is a full-size 100%, according to Chavez.

As apple growers discovered long ago, that change makes all the difference.

“We want to start exploring high-density planting systems where you actually change the architecture of how you will be growing fruiting walls,” Chavez says. Such a fundamental transformation would improve crop load management and, in turn, consummate Chavez’s belief that success revolves around growing fruit rather than growing trees.

UGA STUDY METHODS

Jordan Knapp-Wilson, a PhD Candidate in Chavez’s lab at the University of Georgia, in collaboration with Alexander Bucksch, Computational Plant Science Lab at the University of Arizona (and formerly a researcher at UGA), began their research under the premise that quantifying crown architecture helps dictate the selection of trees that will require less pruning or naturally excel in specific growing/training system conditions.

Knowing the manual collection of branching data for peach trees has been tedious, time-consuming, and prone to human error, they circumnavigated the process by using terrestrial laser scanning (TLS) to obtain digital twins of 16 real peach trees. TLS generates three-dimensional (3D) point clouds of tree crowns, wherein every point contains 3D coordinates.

Each young tree was scanned in 2021 and 2022 and then modeled and quantified using open-source software TreeQSM. The resulting in silico branching data and biometric data for the young peach trees were calculated to demonstrate the capabilities of TLS phenotyping of peach tree crown architecture.

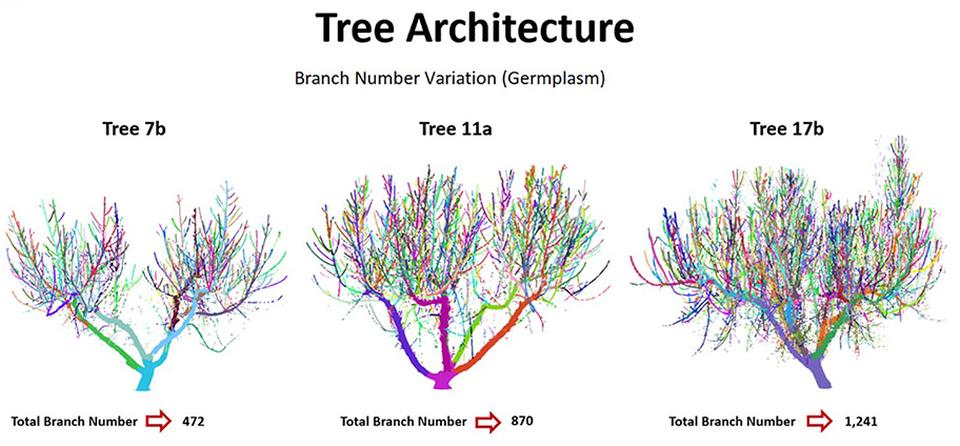

“We are interested in these variations. These are different cultivars,” Chavez says. For example, three such cultivars produced the varied total branch numbers of 472, 870, and 1,241. This, Chavez says, is what gets his blood flowing as a peach tree breeder.

“Can I breed for a cultivar that can produce a lesser amount of branches but produce the same amount of fruit? I think it’s possible,” he says. “But we don’t have the tools to be able to characterize architecture. Nobody really has thought to do that. Everybody’s breeding for fruit, but people kind of forget about the tree in peach production. They want a big peach tree in general, but you don’t think that maybe you want a smaller peach tree that you don’t need to prune that much but produces the same amount of fruit?”

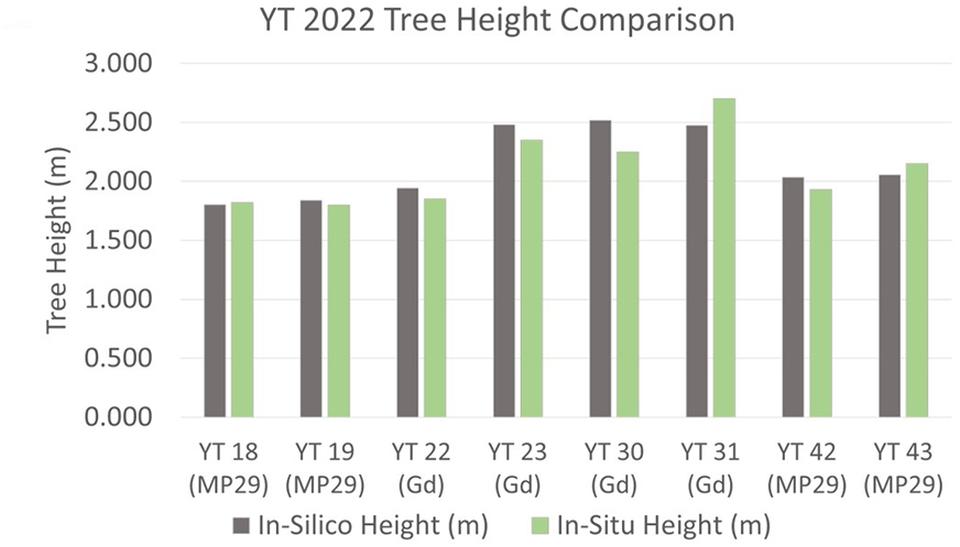

The trial also fared well in terms of the comparison between the in silico branching data and in situ measurements. The mean average deviation when comparing young tree height was approximately 5.93%, with crown volume at approximately 13.26% across both 2021 and 2022.

“They matched pretty nicely,” Chavez says. “The 3D models will allow us to have an in silico database of germplasm year after year, where we can go and mine data whenever we want to and also look at genome regions and maybe allow us to establish certain relationships for breeding and genetics.”

In the long run, peach growers will be able to scan trees before and after pruning to create machine-learning algorithms. Artificial intelligence then mimics what those growers are doing in the field while deciding which trees can be pruned and which trees cannot.

“You can go a step further where you have a UAV (unmanned aerial vehicle) fitted for pruning shears use that data or that information to make the decision to be able to go in an orchard and actually prune the trees,” Chavez says.

Even apple growers would be envious of that advancement. As it is, peach growers will have to continue playing catchup themselves, at least for a few more years, Chavez says.

“We’re at the point where there could be revolutions for the peach industry production-wise within five to 10 years. What I mean by that is growers could start trying new things and hopefully start having some success with certain training systems,” he says.

“In the beginning it’s going to be a lot of errors and a lot of situations that are going to be maybe not so good. But my ideal thing is that in the next five to 10 years we have a catalogue where we have rootstocks X-Y-Z and scions X-Y-Z, and we can give out recipes for training systems and planting densities. From our perspective, we’re excited just because we have some options now.”