Farm Equipment Speed and Accuracy Help Lighten the Load of Labor Issues

The current state of vegetable planters and transplanters revolves around minimizing labor costs and shortages while improving accuracy and speed in the field. American Vegetable Grower® magazine inquired with three equipment manufacturers/suppliers — Checchi & Magli (C&M) North America, Mechanical Transplanter, and Sutton Agricultural Enterprises — to better guide vegetable growers across the country.

Here’s what they had to say.

Sutton Agricultural Enterprises

Vegetable farmers are striving to improve their planting accuracy in 2023, according to Joseph Sutton, Operations Manager of Sutton Agricultural Enterprises in Salinas, CA. With more of them adopting automated cultivating, thinning, and harvesting, exact plant spacing “has become more critical than ever before,” Sutton says.

Past tendencies often lead growers to overlook the importance of seed spacing, which is dictated by seed drop distance and planting speed, Sutton says.

Wizard vacuum planter.

Photo courtesy of Sutton Agricultural Enterprises

“It is common to plant at too fast of a speed and with older-style equipment. The use of newer vacuum planters along with planting at the correct speed will give much more accurate planting results,” he says.

The most accurate and precise planters on the market are vacuum planters, such as Stanhay (United Kingdom), Sfoggia (Italy), and Wizard (Italy), according to Sutton. “Many of our customers are using these planters to more accurately seed their crops, allowing for greater yields, seed savings, and ease of use when cultivating, harvesting, and thinning.”

Mechanical Transplanter

Although not many actual growers come to his facility in Holland, MI, the ones who do, according to Mechanical Transplanter Co-owner Dan Timmer, all say the same thing: “I can’t find enough help, and things are getting so expensive.” Unfortunately, Timmer says, “I do not see things getting better on either of these issues.”

That is where Mechanical Transplanter steps in. “Our transplanters can help on the labor side of things,” Timmer says. “We have transplanters for almost every type of seedling.”

Model 948 single-row mulch transplanter.

Photo courtesy of Mechanical Transplanter

Timmer has seen a shift to his company’s plastic mulch transplanters among local growers. The 912/948 mulch transplanters use less labor than hand transplanting and are “way more” efficient than the typical “water wheel”-style hand transplanter. “One person on the transplanter and a tractor driver can get a lot done in a day,” Timmer says.

Mechanical Transplanter also manufactures a fertilizer side dresser that puts the fertilizer right where it needs to be. “I have heard growers mention using 50% to 75% less fertilizer vs. just broadcasting the entire field,” Timmer says.

One tip from Timmer: “I feel it is best for growers to talk with the equipment company early when purchasing new transplanter equipment in case adjustments need to be made in the greenhouse. We can suggest the proper cell size for growing the seedlings to maximize efficiency when going to the field.”

Checchi & Magli (C&M) North America

This year is all about speed and efficiency, compelled by weather challenges and rising labor costs, according to Cameron Hill, Director of North America, Checchi & Magli (C&M) North America. “Consider California’s proposal to raise the minimum wage to $22-$24 per hour. Or over-time pay starting at 40 hours in some states. These rules, combined with unpredictable weather, require growers to plant as fast and efficiently as possible,” Hill says.

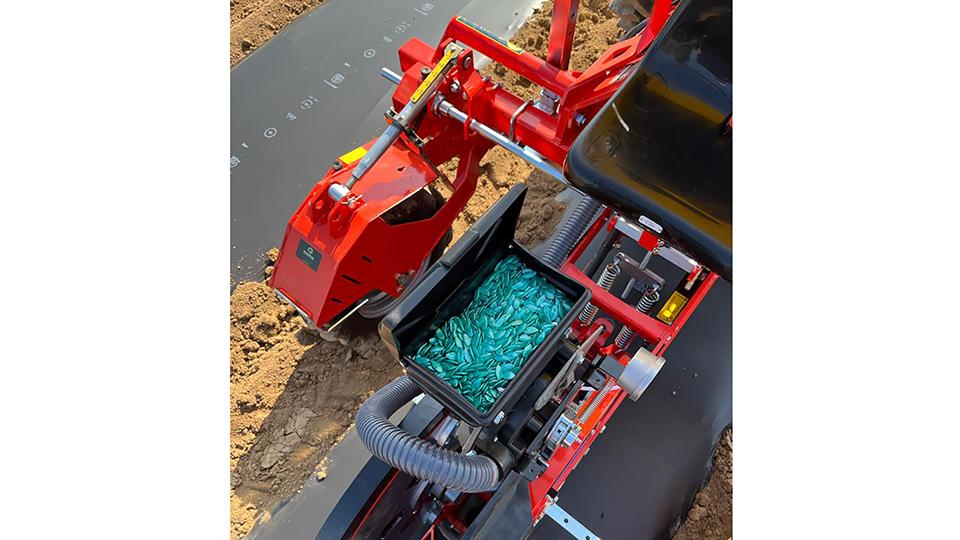

Wolf Pro transplanter with SeedPro seeding unit.

Photo courtesy of C&M North America

Growers should invest the time to get their machines dialed in, Hill says. “You will save money. The consistency should be close to perfect. You shouldn’t need multiple people following the transplanter. The plants should be well packed, straight up, with the correct water quantity, etc.,” he says. “This will all increase efficiency and improve yield.”

Checchi & Magli aims to help growers operate faster, whether planting through plastic or into bare ground. “A tomato grower recently was planting with our eight-row Trium at over 2.3 mph, and with only one person following. That’s significant time and labor savings,” Hill says. “Our adjustable timing and smooth rotation allows for increased speed while maintaining a consistent, packed, and straight plant.”