New Tank Mix Simplifies Application of Innovative Plant Growth Regulator

With the recent Environmental Protection Agency (EPA) approval of Harvista™ Mix from AgroFresh, U.S. growers of apples, blueberries, cherries and pears can now conveniently apply Harvista 1.3 SC, the highly regarded, near-harvest plant growth regulator, without the need for specialized equipment.

Launched in 2014, Harvista 1.3 SC is the only plant growth regulator available that delivers fast-acting control of ethylene response up to the day of harvest, which expands the harvest window. For apples, that means reduced fruit drop and better quality, size, firmness and color development. For blueberries, increased firmness and more marketable yield. And for cherries, increased fruit set and yield.

Recent produce trends further underscore the benefits of maintaining fruit quality in this way. For example, a larger harvest window has proved beneficial when dealing with labor-related challenges. It can also enhance the “you-pick” experience at agrotourism farms.

“We know firmness and other positive attributes have been improved through genetics over the years, said Juan Francisco Vargas, AgroFresh’s Technical Service Manager for the Eastern U.S. “Harvista is able to offer similar benefits—and others—through ethylene management.”

Vargas goes on to discuss how the goal in developing Harvista Mix was to encapsulate the 1-MCP molecule that’s pivotal to Harvista’s ethylene response benefit in a way that provides the traditional advantages of Harvista without the need for specialized equipment. As the application options have expanded, so have the crops on which trials of Harvista have been conducted and approved for use.

Harvista’s unique mode of action inhibits ethylene production, allowing for more marketable yield potential by offering greater flexibility in fruit ripening before, during and after harvest. Blueberry growers who have used Harvista have also reported notable results:

“We had excellent results with the pre-harvest application of Harvista on blueberries,” says Brandon Wade, Plant Manager of Alma Berry Farms. “More specifically, we saw an increase of around 10% in pack out on Legacy and Camellia, 5% on Optimus, and around 2% on Suziblue. In addition, the packing line ran much more smoothly with the firmer berries.”

Wade went on to note: “If you set the lugs from the field side by side, there was a noticeable difference between the treated and untreated berries. The treated showed dramatically more consistent and firmer berries. The service provided by the AgroFresh team is amazing. They were there from start to finish, walking us through every part of the process.”

When applied to your cherry blossoms (between 10% and 50% bloom), Harvista technology interrupts the negative impacts of ethylene and allows more blossoms to develop into fruitlets, enhancing yield potential and driving revenue. Growers report significant impact on yield with two applications of Harvista.

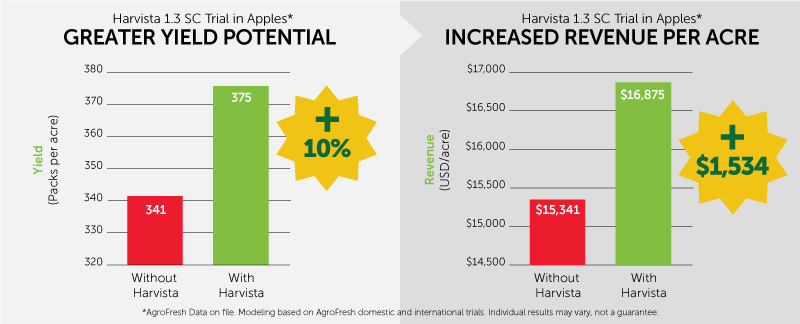

With over 10 years of use in the field, apple growers using Harvista with their Honeycrisp and Red Delicious apples show positive benefits, such as larger fruit with more color development, maintained pulp firmness, and delayed starch degradation so fruit has better conditions for long-term storage. Overall, this near-harvest tool facilitates easier harvest scheduling and positively impacts labor management because of the harvest window being extended. In addition, growers see a significant reduction in fruit drop, ultimately reducing fruit and food loss in the orchard destined for the consumer. The results of Harvista Mix are comparable to those seen when using the specialized equipment traditionally used for Harvista 1.3SC applications.

“Harvista Mix is just the latest example of how we’re empowering the business of fresh at every step,” said Rodrigo Cifuentes, North America Regional Commercial Director at AgroFresh. “Growers can now experience everything Harvista has to offer for ethylene management in the field without the need for special application equipment. Harvista Mix can be used with regular sprayers without the need of injection equipment, creating more opportunities to continue expanding its uses across crops and throughout the growing season.”

Harvista is part of an integrated, data-driven system to help support superior quality management. Growers can pair Harvista with FreshCloud™ digital solutions for block harvest optimization and post-harvest quality tracking, and with the SmartFresh™ quality system to maintain fresh-picked quality all the way to the consumer.

More details about Harvista Mix and other ways AgroFresh, the global leader in post-harvest solutions for fresh produce, is helping customers produce abundant, sustainable, quality fresh produce are available at AgroFresh.com. To connect with a local sales representative, contact [email protected].