Breakthroughs in Auto Weeders Keep Coming for Vegetable Growers

After all the automated weeder, automated harvesters, and precision sprayer articles I have written for American Vegetable Grower, I thought maybe I should give those topics a rest.

But as I researched topics for the Automated Technology Field Day in Salinas, I realized I need to address several noteworthy new machines that significantly change our ability to control weeds.

Auto Weeder Challenges

In the last five years, our ability to control a significant portion of the weeds with automated weeders has greatly increased.

There are several companies with machines that use a split blade operating in the Salinas Valley that remove weeds from the seedlines. The machines use cameras to detect weeds and crop plants, computers to distinguish between the two, and a kill mechanism that safely removes the weeds from the crop.

We have tested these machines and found they are capable of removing 70% or more of the weeds in the seedline.

One of the challenges of the current technology is that they are not capable of removing weeds that grow right up against the crop plant. The split blades cannot get closer than 0.5 inch or so to the crop plant. They risk cutting roots and reducing crop growth.

Another weeding challenge are crops that are planted at high densities on 80-inch-wide beds. These crops are planted so close together that cultivation of the bed top is not possible.

Once the crops like baby lettuce and spinach are planted, hand weeding is the only option to remove weeds from fields. There is no effective post emergent herbicide registered for use.

As a result, these crops can often have the highest hand weeding costs of all vegetables.

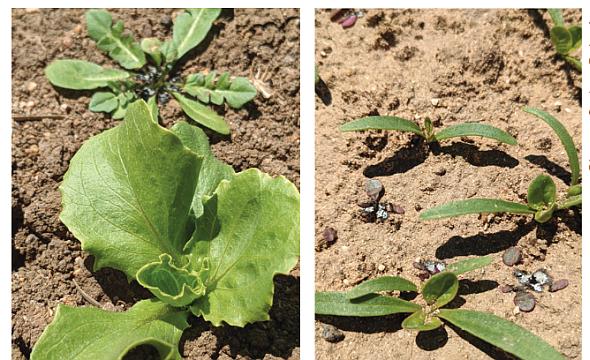

The most expensive weeding is for high-density crops like spinach and lettuce, which require hand weeding for any weed closer than half an inch. New technology may change that.

Photos courtesy of Carbon Robotics

Laser Weeders

Clearly, there is a need for a kill mechanism on automated weeders that can precisely and safely remove weeds that grow close to the crop plants. Several ideas have been proposed over the years, such as precision sprayers that can deliver a dose of a material to kill plants, or even a laser that can be precisely directed to weeds and away from crop plants.

Carbon Robotics, a new company founded in Seattle in 2018, recently came to the Salinas Valley and is demonstrating its machine to growers.

Their machine uses lasers to remove weeds. As the machine moves over the bed top, it uses artificial intelligence to recognize weeds and target lasers towards them to burn the growing point.

At a recent grower demonstration in lettuce planted in double rows on 40-inch-wide beds, reps showed the machine’s ability to safely remove weeds growing within millimeters of crop plants.

The machine was originally developed to remove weeds from onions, a slow- growing crop in high- density stands. That makes them (along with carrots, baby lettuce, spring mix, and spinach) one of the most challenging crops to remove weeds.

This machine uses sophisticated recognition technology to distinguish between crop plants and weeds. Weeds growing right next to crop plants are the most expensive weeds to remove. And this machine can do this with little to no collateral damage to the crop.

This brings us closer to the ultimate goal of automated weeding: removing a sufficient percentage of the weeds to forgo follow-up hand weeding.

Hot Oil Method

In addition to the use of lasers, another company is experimenting with spraying hot oil onto the weeds. Clearly the hot oil has tremendous capacity to kill weeds and, if applied in a precision fashion, it has the potential for also removing the weeds that grow up close to crop plants.

Building on Strength

Both of these examples of new technologies come on the heels of other significant developments in automated weed control. Companies like FarmWise, Robovator, and Stout, as well as the automated thinners developed by Ag Mechtronix, Mantis, and Vision Robotics, and others brought the industry forward in just a few short years. It has come just in time because of other pressures that growers feel such as the regulations regarding pesticides and the lack of adequate labor.

These machines are quite expensive, but growers base purchase decisions on the hope these machines sufficiently offset other costs and/or supply a service that may not be otherwise available.