Cutting-Edge Agriculture Reaching New Heights in Florida

Rolling through Wauchula on Highway 17 in Southwest Florida, it would be no surprise if a passerby didn’t notice the nondescript warehouse located roadside in the small town. But inside the building is a highly sophisticated farm — perhaps a model of the future of agriculture. Under the name Hardee Fresh, the operation planted its first crops in October 2019.

The team at Hardee Fresh had a vision of taking the concept of vertical farming to a higher, more refined level. Vertical farming, like the name implies, takes production up — stacking rows on top of another in a controlled-environment structure. Each row uses LED lights to replace sunlight, and nutrients are fed to plants on trays via hydroponic irrigation. While the building is about 1 acre in size, the growing area inside is about 10 times that. The towers in the facility comprise seven to eight vertical rows of growing space.

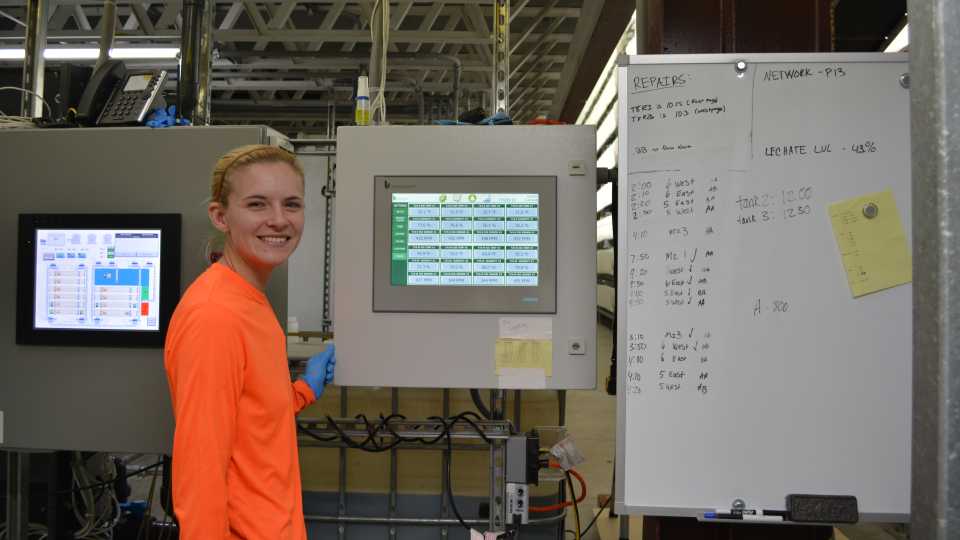

The environment inside the building is highly controlled to optimize the growth and quality of the crops being produced there. According to Dr. Tyler Jacoby, a Co-Founder of Hardee Fresh, there are few — if any — vertical farms in the country deploying all the types of technology being used in the Wauchula facility.

“Some of the technology we have here is among the latest of its kind, certainly in the ag space,” Jacoby says. “We can create the perfect microclimate on each level of the rows with perfect temperature, humidity, and carbon dioxide levels. We can control everything. There are 7,700 LED lights in the facility, and the 11 HVAC handlers are moving a tremendous amount of air (300,000 tons) through the building.”

The farm is utilizing a technology that powers LED lights inside the building via digital electricity. This allows the farm to generate exponentially less unwanted heat in the growing zones in comparison to compact fluorescents, metal halides, or even other traditional LED systems.

Fine-Tuning Nutrients

Clint Hunnicutt, Hardee Fresh’s General Manager and Head Grower, has been working to develop nutrient regimens for the various leafy green crops being grown in the facility. Nutrient programs in hydroponic farming can be tricky. This is especially true in organic production.

Hunnicutt says organic nutrient sources are limited, either coming from fish and other animal sources or plant-based nutrients.

“We need formulations that are immediately available to the roots in the hydroponic solution,” he says. “We don’t have the benefit of soil biology like in open fields that help make nutrients available to the plants.”

The farm is using an ebb-and-flow hydroponic system. Nutrient-rich water floods growing trays for a period of time and then is drained several times per day. Hunnicutt says they have taken commercial organic products and tweaked them to fit the crops being grown in the farm.

“We have a base organic nutrient mix, and it works well on leaf lettuces,” he says. “Now, we are testing other varieties outside our main crops to see how they work with the same type of mix. If we see we need more calcium or more of this or that, we will add it to the mix based on the crop’s needs.”

Mind Your Media

Hunnicutt says another big piece of hydroponic growing in an ebb-and-flow system is the selection of media. They have chosen organic coconut coir media sourced from Sri Lanka. The coir cubes are hydrated, and seeds are planted in them and grown out for about 10 to 14 days before being moved into the vertical growing towers.

“The coir gives us sort of an insurance policy when compared to a nutrient film technique (NFT) hydroponic system where there is a constant flow of water on the roots,” Hunnicutt says. “If we were to lose our ability to flood the trays, which we shouldn’t because we have a ton of redundancy to avoid that, the cubes retain moisture and nutrients. In an NFT system, if the water stops, plants are wilting within 30 minutes. In our system, we’d have a couple of days because of the coir.”

Total Water Control

Water is the heart and soul of any hydroponic system. Hardee Fresh uses computer controls to manage water at an extremely precise level.

“We flood our trays to about 1 inch or 11/4 inches of water, or about halfway up the sides of the coconut coir,” Hunnicutt says. “We apply the water, and as soon as it is done, we drain it. We don’t hold the water for any amount of time. We flood and drain, and flood and drain.

“We irrigate more than the crop’s water needs. It is all about nutrient replacement in the media and roots. We mix up a batch of nutrient mix with our water and flood the various towers throughout the building. We recycle the water. It is a very efficient system when it comes to water usage.”

After trays are flooded, the water is returned to a holding tank. For example, Hunnicutt says if 1,000 gallons of water are applied to a growing section, up to 900 gallons will be returned. When it is time to mix a new batch for irrigation, recycled water is sanitized and returned to the batching system, and makeup water, along with nutrients, are added to the mix to satisfy the requirements for that batch. The makeup water used is run through a carbon filter, softener system, a reverse osmosis system, and ultraviolet light treatment to clean and purify it. “It is pretty much the purest water you can get,” he says. “Then we use that water to make up for what has been lost to absorption by the media and transpiration by the plants.”

Lights Power Growth

Another key component of the vertical farming system is the LED lights that fuel photosynthesis and plant growth.

“Right now, we are using generic cycles for lighting the growing trays,” Hunnicutt says. “Most leafy types respond similarly to lighting. The key with the lights is not to push the plants beyond their ability to grow, because tip burn is a common result of overdoing it. If you run your lights too long, you are going to get tip burn no matter how many nutrients you feed them.”

As the growing system is fine-tuned, Hardee Fresh will plant and harvest product every day, year-round. “We are getting it figured out, learning how different crops respond, and tweaking to fit its various needs,” Hunnicutt says.

Marketing Food Safety and Quality

Retail buyers are more focused than ever on growing practices’ impact on food safety, especially in leafy greens. Jacoby notes Hardee Fresh’s food safety protocol will be a key selling point of the product coming out of the farm.

The tightly controlled environment is designed to avoid contamination. It is a matter of keeping out pests and pathogens, and there are various protocols to achieve this goal. An extensive food safety plan is followed by all employees that includes personal protective equipment as well as daily cleaning and sanitizing of the facility. Hardee Fresh also deploys an extensive microorganism/biological testing program that includes the production, harvesting/packing, and cooler areas of the building. In addition, all water sources are tested daily for food safety requirements.

On top of that, buyers like the organic label and the fact that no pesticides are used in the facility. “The sustainability message resonates with the retail market and consumers,” Jacoby says. “We’ve also had a ton of interest from restaurants because they like that message and the consistency of the product we deliver. They know they are going to get the same quality product every time, delivered in a timely manner.”