How HortTech Is Solving Grower Challenges

With contributions from Josette Lewis.

For the past few years, you’ve probably heard from a lot of companies touting technological advances that promise to help you do your job more efficiently and effectively.

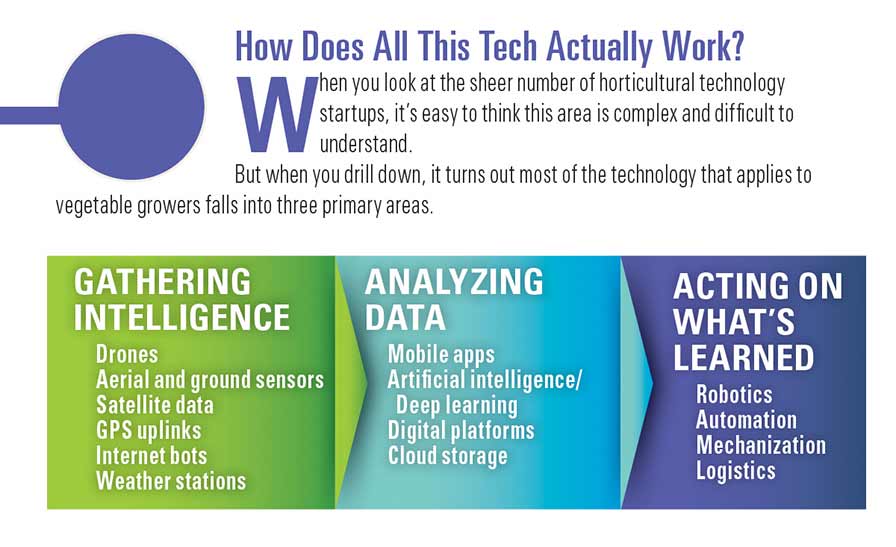

And you’re forgiven if you’re taking a “wait-and-see” attitude about the whole thing. It’s easy to be overwhelmed by the 20th new way to use drones. But if you take a step back, and look at what all those researchers are introducing through the lens of real-world challenges vegetable growers face, you’ll have a much more encouraging view of new technology.

To that end, American Vegetable Grower® magazine wanted to see what’s really out there on the horizon — or even closer. We took a look at research being conducted by the 50 companies THRIVE AgTech (an incubator organization supporting horticultural technology development) identified as the most promising new agricultural tech companies. We then compared those companies’ goals with the real-world issues growers face. Here’s where we see the most promising intersections between their technology and your needs.

The splashiest solution in labor scarcity is using machinery to replace people. Automation and robotics understandably get the most attention from within the industry.

That said, the vegetable industry has adopted automation and robotics more slowly than its peers growing other crops. Why? Mainly, vegetables vary more in shape and have more delicate structures.

But that is now changing. Programing that allows cameras, special software, and mechanics to work together has advanced far enough that growers of tomatoes, peppers, and other crops are successfully using the technology for packaging and even harvesting.

Another way modern tech is helping labor is logistics, or using intelligence to eliminate or reduce when and how often tasks are performed.

Today, data collection can identify inefficiencies and optimize labor resources. It can pinpoint timing for when irrigation, spraying, or harvesting is needed. It also allows managers to more accurately schedule time in the field, transportation, harvesting, and so on.

Another more subtle technological advance is how transparent the hiring process is now through information technology apps.

Labor-related paperwork is being made easier as well. Technology reduces paper between labor and

HR accounting.

Challenge: The need to reduce costs

All the information that drone systems, sensors, and satellite data gathers allows growers to have much more precise mapping of what’s happening in their fields. With that knowledge, you can increase accuracy in applying crop protection products, knowing exactly when to irrigate, and cutting out unnecessary applications.

The advances in GPS or GIS (geographic information system) software are helping growers get the maximum available planting out of each field. By hooking GPS into tractors, straighter rows with the exact same spacing can add a row (or two or three) in the same space used in previous years.

Another way to cut costs can be found in new predictive software, which uses algorithms for more precise timing of harvests, as well as in irrigation and crop protection. The ideal situation isn’t that far off: Artificial intelligence will analyze the data, recognize problems, then alert growers even as automated irrigation is scheduled. Driverless tractors are now being made into prototypes, so automating weeding and spraying is already available, and will continue to be developed, improved, and become more affordable.

One area of advancement that just about all growers are already enjoying is in steadily more energy efficiency in existing machinery, from irrigation pumps to processing equipment to refrigeration technologies.

Challenge: The need for higher quality crops

An important way to increase profit is to improve quality, not just yield. Many of the cost-saving technology has the added benefit of aiding in crop quality.

In-field packaging, automated postharvest handling, and new packaging technologies that don’t damage the plant and increase preservation allow growers to demand more for their efforts. New fresh pack product innovation also increases value to consumers.

Challenge: Food safety

One of the most important aspects of food safety, from a regulation point of view, is documentation. And it turns out that GPS-fed software is really good at tracking your laborers’ activities. Software platforms link sensors to regulatory recordkeeping. Think of it as the Fitbit for food safety.

Like the ubiquitous Fitbit, electronic tracing technologies are now low cost and affordable to just about every grower.

Other ways technology can help growers meet food safety rules include allowing automation to reduce microbial contamination risks, getting test results more quickly, using in-place cleaning software, and standardizing protocols in packaging and processing facilities.

Cloud technology, GPS-connected tracking, and app software are making food-safety related paperwork easier to handle as well.

Challenge: Changing demands from customers and retailers

Retailers have a lot of power over how growers operate.

Those retailers with outlets all over the country are wanting growers to provide locally grown produce, even when the grower isn’t near those locations. Several researchers are deep into urban growing technologies that allow protected agriculture sites to be established quickly and affordably, so even smaller growers will be able to provide a multi-state grocery store with locally produced crops.

Retailers are also passing along their customers’ demands for sustainability, food safety, and responsible farming. That’s where software that can certify traceability becomes a key selling point. For sustainability demands, growers can prove that they’re not overfertilizing or using pesticides in a way that harms the environment with tracking and documentation software.

Challenge: How to make sense of all this data

Decision-support software platforms can now integrate data from multiple sources, helping you see all relevant data at once, making it easier to decide the timing and amount of inputs with more confidence.

And there’s actually A.I. (artificial intelligence) being developed that will figure out what to do with big data so you don’t have to.

But don’t write off humans too quickly. Grower-led validation of all this technology will give real-world feedback on how well it all actually works.

Lewis is Associate Director of University of California, Davis World Food Center.