How To Create Process Budgets for Farm Equipment

Some things are easy to budget for. You know how much seed goes into your field. Fertilizer and pest controls, ditto.

But farm equipment isn’t as straight forward when you’re calculating costs per acre.

University of Massachusetts Extension has a series of online crop budgets, organized by crop, that walk you through how to factor in those costs.

Establish the Basics

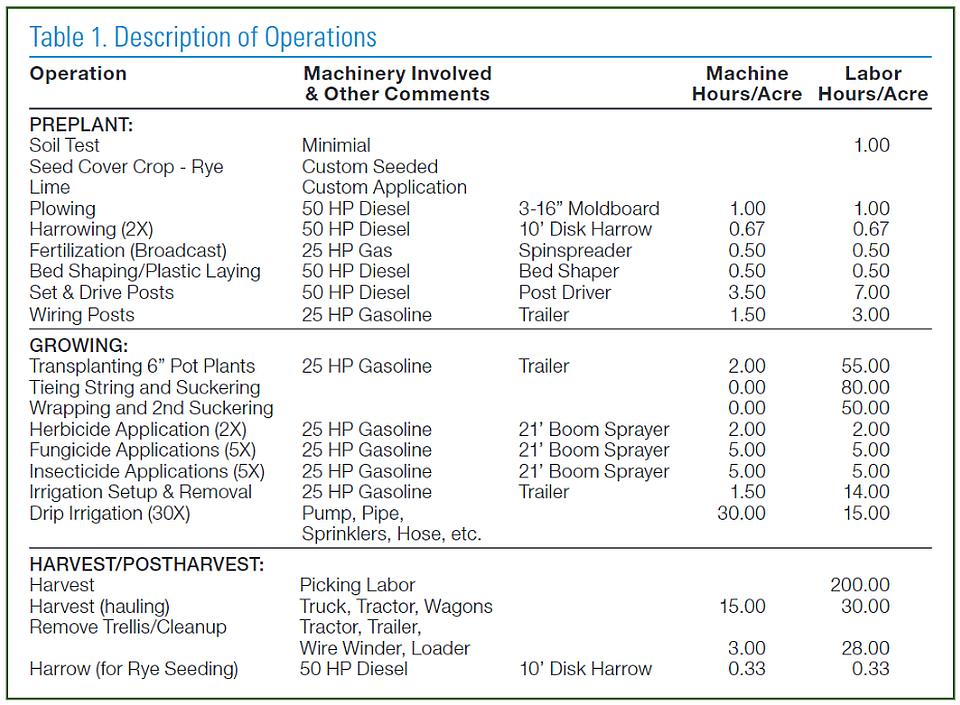

It starts with breaking down what equipment is used throughout the season and assigning machine hours and labor hours per acre.

Take a look at this sample budget listing for trellis tomatoes. This particular budget targets smaller farms with one to 10 acres of trellis tomatoes.

Labor and Materials Budgets

The next step is to calculate labor costs using the labor hours you assigned in the Description of Operations by multiplying it by how much you pay workers for different tasks per hour, whether a skilled or unskilled wage.

You then do the same analysis for materials costs. Take pesticides, for example. You’ll specify the units used (gallons or pounds), the price per unit, and the quantity applied.

These two tasks are straight forward budgets you’re likely already using.

Machine Costs

Now let’s tackle machine costs.

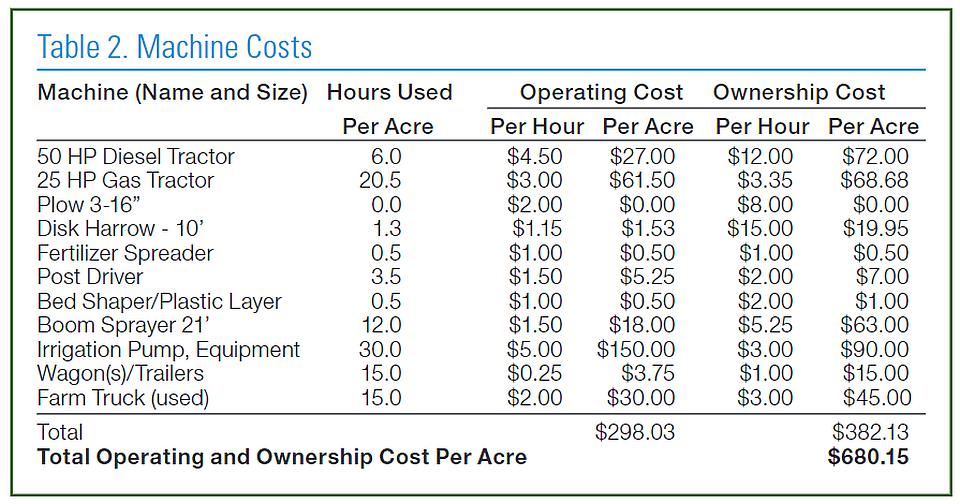

University of Massachusetts breaks down the uses by hours used per acre, operating costs, and ownership costs.

Here’s how that looks for our tomato trellis.

Take the time to visit the full sample budget on the University of Massachusetts Cooperative site. It includes 11 crop budgets to help you zero in on the nuanced costs it’s easy to overlook.