Juice Up Your Fertilizer Program with Recycled Cover Crops

Editor’s note: USDA/ARS’ Eric Brennan explores an unusual idea to radically improve the sustainability of vegetable production. You can watch his video, “Juicing Cover Crops … Are You Nuts? Maybe, But Hear Me Out,” or read an article version of his proposed idea below.

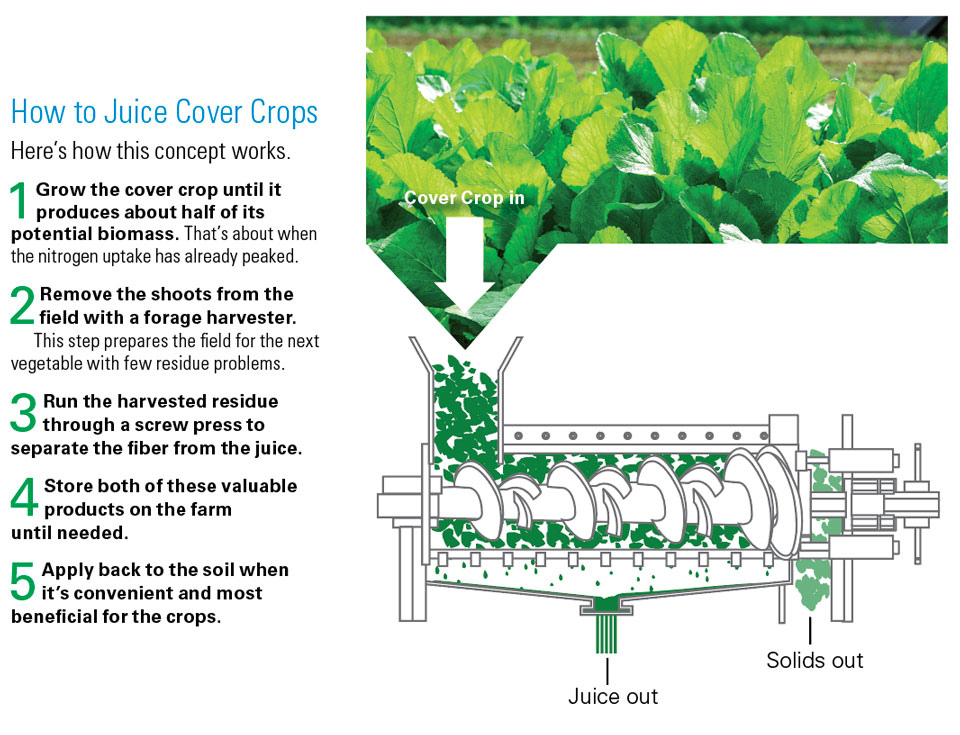

I would like to share a somewhat crazy idea with you, one I think may work well to increase the use of cover crops on vegetable farms in high-intensity production regions like Salinas Valley, CA — pressing cover crops to make a juice, i.e., a low-cost liquid fertilizer. My goal is to give you some details on how I think this has the potential to radically improve the sustainability of high-input crops.

Unlike most studies I conduct, this idea started humbly as a home experiment. I was looking out my kitchen window at a garden bed of mustard cover crop growing in the backyard.

I wondered — what would happen if I put some mustard shoots in a blender with water, strained it, then applied the liquid to plants as a fertilizer? Could I transfer some of the nutrients from the dark-green mustard into a few of my stunted houseplants?

So for several weeks I gave two of the houseplants that juice and the other two unlucky ones just water. The results were pretty dramatic!

Those results spurred me to dig into the issue by setting up several replicated studies with cover crop juice at the USDA greenhouses in the Salinas Valley.

I learned quite a bit in those studies. Let me answer some questions I’m sure you have about what I found and if it’s something you should pursue.

What’s in the Juice?

How much juice can you produce and what’s in it? Based on my research thus far, here’s what I think we can expect.

The mustard starts out with about 80% to 90% moisture and a pretty low carbon-to-nitrogen (C:N) ratio.

After it’s been macerated and juiced, the fiber has about 50% to 60% moisture, and the C:N ratio is about twice as high as before juicing. About half of the NPK in the original shoots ends up in the juice, so that’s a pretty good amount of nutrient content in that juice.

Let me put this into perspective with a scenario. Let’s say that we grew 5 acres of mustard and it produced about 10 tons per acre of fresh shoots. For the 5 acres, that would be about 6,500 gallons of juice, which I estimate would have about 250 pounds of nitrogen.

It’s true the mustard juice would have relatively low nutrient concentrations compared with commercial, liquid organic fertilizers. But — and this is important — the juice is produced on farm from nutrients that otherwise would have been wasted. I say wasted because nitrogen would likely leach out of the soil and into the groundwater during the winter if the field had been left fallow. Nutrient leaching is a big problem in the Salinas Valley.

What About the Leftover Fibers?

After you press the cover crops, you not only get liquid fertilizer, you also have the leftover fiber.

I think that press material or fiber would be perfect for storing in silage bags and then using later as compost. For that 5 acres of mustard, I estimate we’d only need a 25-foot long, 8-foot in diameter silage bag to hold the pressed mustard shoots. So you can see, we’re not talking about that much space to store the juice or the fiber component.

Why Use Cover Crops?

Cover crops aren’t free. And a lot of large-scale growers aren’t using them currently. If you drive around the Salinas Valley, you’ll see lots of bare fields.

All these bare fields during the winter rainy season, from October to about March, allow lots of leftover nutrients from the previous year’s crops to leach out of the root zone and pollute our groundwater. And we use that for drinking.

A major reason cover crops aren’t growing very often in these systems is because the cover crop residues are difficult to deal with when you’re transitioning from a cover crop to the next vegetable. And that’s where the juicing idea might help to make cover cropping more convenient and these systems more sustainable, basically by giving the grower more control.

What Equipment Can Press Cover Crops?

Fortunately, much of the equipment that would be needed to make this process work has already been developed by the dairy industry.

For example, a large screw press like what’s been used to de-water manure would be ideal for extracting the cover crop juice. In fact, I saw one of these in operation on a recent trip to Denmark where the scientists are working to extract the protein-rich juice from forage crops. They use this protein for pig feed as a potential alternative to imported soybeans. There’s actually quite a lot of research in this area going back several decades that can be applied to this cover crop juicing idea.

Will It Save Money?

I think the juice we produce might actually be a cost-effective source of liquid organic nutrients and more sustainable than other commonly available commercial products.

Let’s do a little back-of-the-envelope math based on a 5-acre scenario.

Potential Dollar Value of the Juice. Let’s say an organic strawberry grower pays about $18 per pound of nitrogen for the liquid organic fertilizer. And at that price, that 250 pounds of nitrogen (which we extract from the 5 acres of mustard) would be worth about $4,500.

Dollar Value for the Compost. The press residue stored in that silage bag would likely have a value equivalent to compost, or about $1,367.

But we still need to subtract the cost to grow the cover crop, to harvest it, and then to juice it.

Planting and Harvesting Costs. The planting costs for a mustard cover crop are about $250 an acre. That’s about $1,250 for 5 acres.

Juicing Costs. The big unknown question is what it will cost to juice cover crops. We should also factor in the cost to store the juice and the residue.

How We Can Make This Work

What I envision is growers would use a service company, one that normally sells fertilizer to farmers or make their beds for them, to help with the cover crop juicing process. That company would own a mobile cover crop processing unit that could move from farm to farm and leave the grower with a silage bag with press residue and a tank full of cover crop juice.

The same equipment could also be used to harvest and extract nutrients from cash crops, like broccoli, that are loaded with nitrogen after harvest. Actually, it could also extract nutrient-rich juice from vegetable waste at processing plants.

I must admit there are lots of questions that we need to address to see if this novel idea of juicing cover crops will work on a commercial scale. But as I continue to do research on the various components of the process, I remain optimistic that it has the potential to increase cover cropping in some high-value, high-input vegetable crops in regions like the Salinas Valley.

So what do you think of this idea? A great way to join the conversation would be to add a question or comment to the YouTube video where I described this in more detail.

So stay tuned as I continue to work on this research.