Smart Sprayers Now Multitasking in the Field for Lettuce Growers

Smart sprayers that apply spray materials directly to the targeted plant and not to the surrounding soil have been dreamed about and discussed by growers for many years.

An early example of this type of technology is used in vineyards in which an infrared sensor directed to the ground beneath the vine canopy turns the sprayer on when it detects weeds and turns the spray off where there are no plants thus saving material costs and reducing pesticide load in the environment.

Recently developed smart sprayers use a camera to detect plants, a computer to analyze the image and to activate the sprayer. Smart sprayers now being used in the Salinas Valley are an extension of automated thinner technology.

Next-Level Sprayers

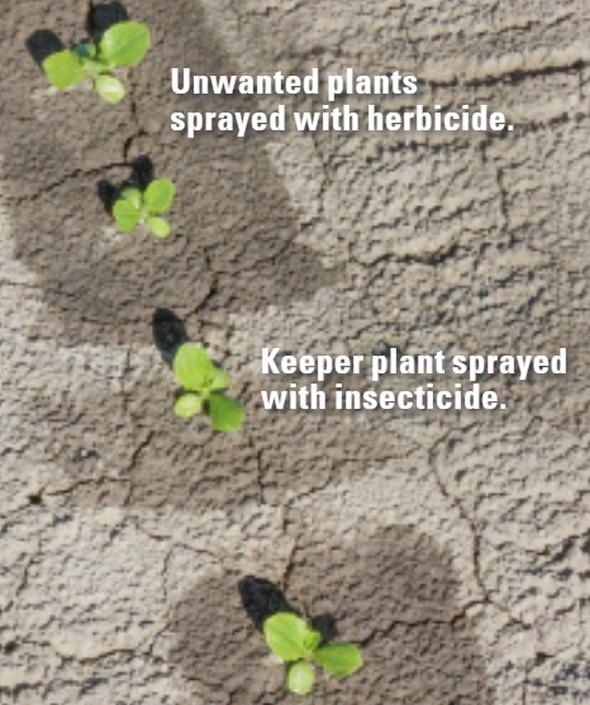

Automated thinners, first available in 2013, sprayed unwanted plants in the seed line, leaving “keeper” plants at the desired spacing.

Autothinner developers (AgMechtronix, Mantis Ag Technology, and Vision Robotics), quickly realized their machines could also spray the keeper plants with pest management materials — such as insecticides and fungicides — at the same time. To this end, they added a separate, secondary beneficial spray manifold to spray the keeper plants. Lettuce is commonly autothinned 18 days after planting, and the beneficial spray manifolds apply insecticides and fungicides as needed at this early stage in the crop cycle.

Mantis Ag Technology is now expanding the use of the beneficial spray system by using its machine as a commercial sprayer to apply insecticides and fungicides from the thinning stage to when lettuce plants get big enough to touch each other. Once lettuce plants get big enough to begin touching one another, the smart sprayer loses its advantage over a standard broadcast sprayer.

One of the smart sprayer’s key advantages is that it applies a reduced rate of pesticides — directed only at the crop plants — and does not spray gaps between plants or between the seed lines.

Depending on the growth stage of the lettuce, this technology uses as little as one-tenth of the material as a standard broadcast sprayer. As a result, the load of pesticide applied per acre may be reduced by as much as 90%. As the plants get bigger, the amount of pesticide applied to the crop increases.

New smart sprayers can apply different applications during the same sweep through the field.

Photo by Richard Smith

What’s Coming Next

Given that the situation changes between thinning and when lettuce plants begin to touch each another, Mantis continues to evaluate new ways to improve the sprayer’s effectiveness and efficiency.

One example is modifying application spray volume and travel speeds. Currently, the Mantis smart sprayer treats three 80-inch-wide beds and commonly travels from 3 to 5 miles per hour. The speed and accuracy of the sprayer is dependent on ultra-fast and reliable solenoids that control spray activation and termination. As a result, the company is experimenting with and upgrading solenoids to help increase the spray pattern’s precision.

Researchers from the USDA and University of California are evaluating smart sprayers to better understand the efficacy of the machines relative to traditional, tractor-applied broadcast applications. Given the applications’ low rates per acre, researchers are interested in the impact of various types of insecticides, such as contact and systemic, and the timing of their applications, to optimize the management of key insect pests of lettuce, including thrips and aphids. The researchers are in the early stages of their evaluations but state that insect control looks very promising with the smart sprayers.

Increased Pest Pressures to Watch for

Given that beneficial sprays can be efficiently applied as early as thinning provides an opportunity to control thrips when the population pressure is high in the Salinas Valley, from early summer through fall. Early sprays can help growers dampen the spread and impact of key lettuce diseases such as impatiens necrotic spot virus (INSV), which has been a serious production concern in recent years.

Growers increasingly face issues in the urban/agricultural interface where they are under increasing pressure and regulations to reduce off-site movement of spray materials. Precision targeting of sprays to individual plants reduces the load of pesticides applied to the environment, which helps growers comply with water quality regulations.

In addition, the shrouded sprayer protects the spray from the wind and greatly reduces off-site spray movement. This allows more precise applications, which is important in areas with adjacent crops or in situations where there may be crews or housing in the vicinity.

Automated sprayers are providing growers with a new and valuable tool to reduce risks and increase the precision and safety of their operations. Smart sprayers provide growers a 21st century solution to 21st century problems.