Tier 4 Regulations Pique Propane Interest

Growers have become increasingly aware of EPA’s Tier 4 emission standards for diesel engines. The standards have been phased in for larger equipment like tractors and now are trickling down to other non-road engines and applications.

According to the Propane Education & Research Council (PERC) — as Tier 4 standards are enforced — propane engines provide benefits, and there’s cost-share funding available to help growers invest in the cleaner-burning technology.

I asked Cinch Munson, director of agriculture business for PERC, to comment on how propane plays in Tier 4.

When Are The Tier 4 Restrictions Being Applied To Irrigation Engines And What Will Those Requirements Include?

Cinch Munson

How Can Propane Engines Help With Tier 4 Restrictions?

Munson: EPA or CARB-Certified propane irrigation engines enable growers to meet strict emissions regulations in a cost-effective and convenient manner. Propane engines are considerably less costly up front than a similar Tier 4 diesel engine, so ag producers save money on equipment costs right out of the gate. Propane irrigation engines also are less expensive to operate and maintain due to lower fuel costs and reduced maintenance costs.

Propane engines have other environmental benefits as well. Propane-powered irrigation systems produce 11% fewer greenhouse gas emissions than diesel systems and 24% less than gasoline-powered systems. In addition, propane can be safely purchased, transported, and stored in above- or below-ground tanks, making it easy to fuel farm applications year-round through an established and reliable supply network. Propane also is non-toxic, insoluble in water, and poses no threat to aquifers, steams, or soil.

Can Propane Engines Curb Theft In The Fields?

Munson: Propane theft is very uncommon. Propane can safely be bought in bulk and stored in above- or below-ground tanks that resist theft. Propane is not as easily stolen as diesel or gas as it requires special transportation tanks. We recently heard from a specialty crop producer in California who switched to a propane/diesel irrigation system, which allowed him to place smaller theft-resistant diesel storage tank facilities on his operation.

Explain The PERC Cost-Share Program. What Should Growers Do If Interested In This Program?

Munson: The Propane Farm Incentive Program encourages growers to adopt new propane technologies on their operations. The program offers a financial incentive to qualifying farmers who purchase new, certified propane irrigation engines or dual-fuel systems, and agree to monitor the equipment’s performance and share their experience through a post-season survey and data collection for one growing season. Propane engines are eligible for $400 per liter of fuel displacement, up to $5,000. Farmers can learn more at Propane.com/farmincentive.

Is There Anything Else You Would Like To Add?

Munson: Clean, American made propane is not a new fuel to farming operations. In fact, 40% of farms in the U.S. use propane in their farming and ranching operations to run pumps and engines, heat buildings, and dry and process crops. But the technology that uses propane continues to improve. PERC acts as a technology incubator, helping manufacturers develop new propane technologies for the farm and then helping develop the markets for those products. We work directly with leading equipment manufacturers to develop new propane technologies that help our nation’s farmers and growers power their farms as efficiently and cost-effectively as possible.

Fuel For Florida Farmers

According to Mike Waldron of Tradewinds Power, Florida growers are clued in on Tier 4 regulations.

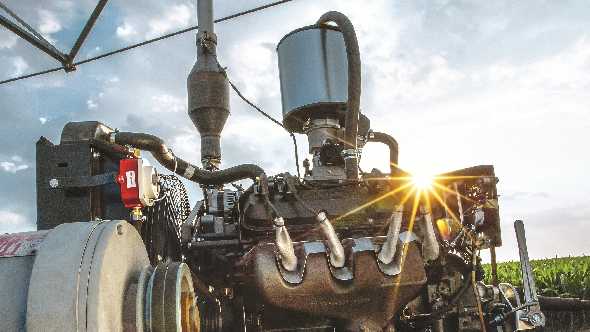

Photo courtesy of the Propane Education & Research Council

“Most all growers are aware of the rules, and some of the larger operations are very aware of the complex EPA regulations,” he says.

“Locally, the innovators are large citrus companies that have budgets to do all the R&D to study the engines. The Midwest is covered with propane users. Overall, most are very interested in learning more about new industrial LP engines.

“Propane is less expensive than diesel per gallon and a propane engine uses slightly more fuel — 30% to 40% more per hour depending on load factors. When off-road diesel is high and propane is below $2 per gallon, the savings is more significant. The LP engines we market are EPA certified and far less regulated than diesel.”

In Florida, Tradewinds sells propane engines that are four cylinders up 10 cylinders for irrigation purposes.